Community Tip - You can Bookmark boards, posts or articles that you'd like to access again easily! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- How can I calculate sheetmetal Length

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How can I calculate sheetmetal Length

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How can I calculate sheetmetal Length

I set K factor in my sheetmetal model. But I don't know How can I check the sheetmetal length is correct or incorrect ?

I find the K factor formula But I calculate the flat length from K factor formula in the Creo Help.

That is different with result in Creo .

Below Picture

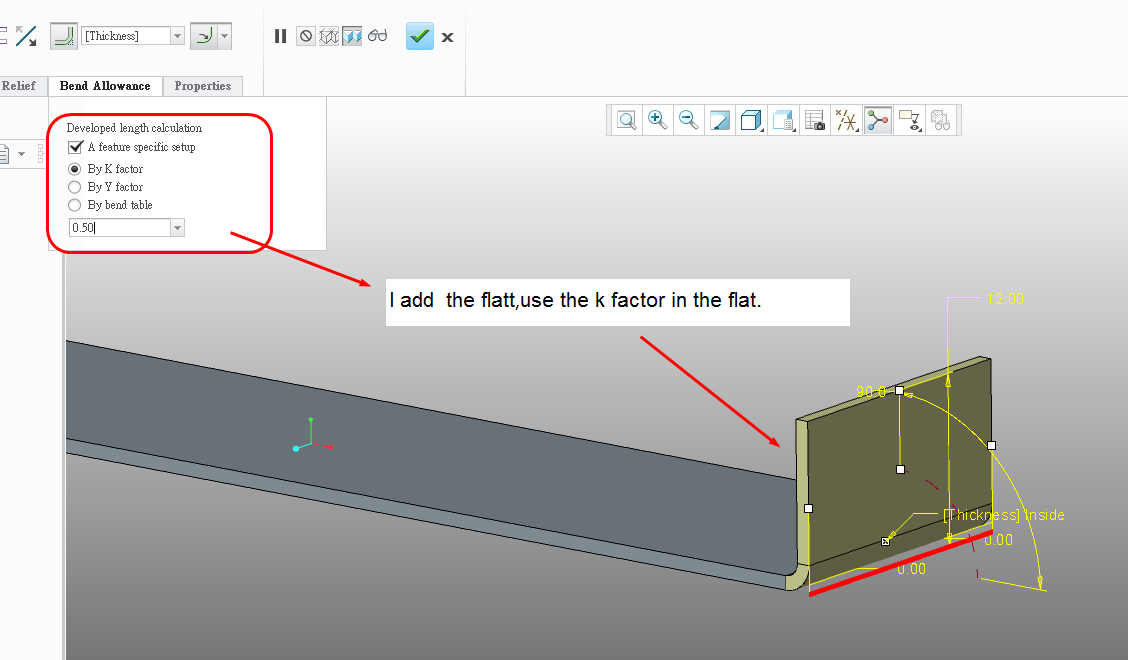

Picture A : add the flat, I use K factor : 0.5

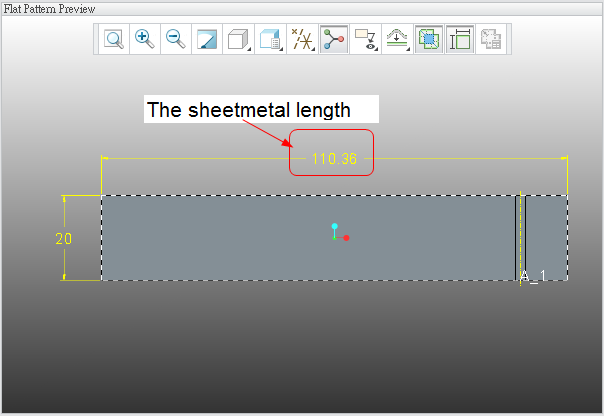

Picture B : What is the formula that can calcalate the sheetmetal length ?

model in the attach

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

Sheet Metal Design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It's been years since I've done these calculations but with a K factor of .5, that is exactly in the middle of your material so if you sketched a "centerline" between your inside radius and your outside radius, you could just measure that length (or calculate that length using perimeter of an arc) plus the straight length on either side.

From a manufacturing standpoint, that would be wrong. Sheet metal stretches as it is bent so it's not exactly a centerline. Depending on your manufacturing, your K factor should probably be anywhere from .33 to .45. It all depends on what material is being bent and what manufacturing method is being used. I can't tell you what K factor you need to use.

Google how to calculate bend allowance. The math is not difficult but knowing the material and manufacturing method is very important to get accurate results.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

When I worked a lot with sheetmetal and A36 steel, we used a K-factor of .44.

Don't forget that Creo uses the Y-factor, from which the K-factor is calculated.

I have this a good introduction to understanding bending.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Calculation:

Blank Length (1 bend) = base length - inside radius - thickness + leg length - inside radius - thickness + (.5 x 3.14 x (inside radius + (thickness x K-factor)))

This matched the Creo flat pattern when I tried it.

There is always more to learn in Creo.