Community Tip - Want the oppurtunity to discuss enhancements to PTC products? Join a working group! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- How to use a family table instance name in a famil...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How to use a family table instance name in a family table (in the reference model column)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How to use a family table instance name in a family table (in the reference model column)

Hi all, looking for some assistance.

I have a need to use the name of a part in a family table, specifically in a cell of a "Reference Model" column. The name needs to be from an instance of the part derived from this same family table. The kicker is, family table editor allows adding the name BUT IT DOES NOT UPDATE if the instance is renamed. The generic name at the top of the column updates as expected. Below are the steps used to initial get the instance name into the cell. Is there another way? I've tried setting a parameter equal to the instance's part or assembly name and inserting the parameter in the family table cell. This does not work, even though the value of the parameter updated correctly the family table apparently does not read the parameters value only the text of the parameters name. Tried using PTC's parameter names for parts, assemblies and common names to no avail. F.Y.I. I know this "Reference Model" column points to an assembly, the assembly instance needing to be referenced and the part instance in question will always have the same name.

This updates the assemblies instance name in the parts family table cell but if the assembly instance is renamed the cell in the family table does not update.

Thanks in advance

MT_WashPA

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Are you using a PLM system, like Windchill?

What version of Creo are you using?

Can you upload your assembly and the family table?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

BenLoosli

Thank you for your attention.

No PLM in use (and none available).

Using Creo 4.0 m140

Models and drawing attached. Note the drawing was created and noted to show another problem, the cutout created in Creo 4.0 did not rotate in the family table instance even though the datum planes used to assemble the controlling model are rotated. The cutout created in older versions does rotate as needed. There is another thread for this problem. Adding the "Reference Model" column in the parts family table fixed the rotation problem with the new cutout, these models have both cutouts old version (the lower) and Creo 4.0 (the upper).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

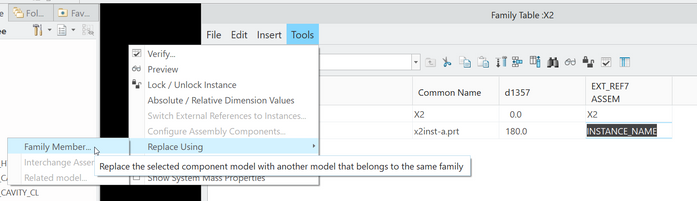

Hi @MT_WashPA , I tried on my system (M150 Creo 4), and if you rename the assembly instance by modifying the family table of the assembly's generic, then you can simply use that function "Switch External References to Instances" in the Tools menu to update the part's family table ref. model column with the new name of the assembly instance.

That all sure sounds very confusing when I read it out loud, but I hope it makes sense and works for you.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

success. Worked once but does not act like it's a permanent solution.

Will try again tomorrow.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello @MT_WashPA

Please consider first that usage of Switch External References to Instances capability CREATES (and DOES NOTUPDATE) the Family Tree of Affected Component whose instance name was changed.

- This is expected & officially documented in To Automatically Update References to Assembly Instances section of Creo Parametric Help Center as follows:

The components which have external references will be listed and those references will be proposed as new instances.

- And this is therefore probably something you don't want

Then, please consider that this buisness need:

- Is fully covered and supported in the scope of PLM systems, like Windchill:

- This is due to the fact that PLM Systems ensure "Dependency Tracing" when doing things in Creo (Save as, Rename, etc ...)

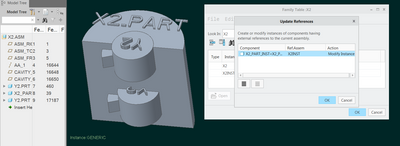

- This is illustrated in the little first demo attached with your files while Interacting with Windchill PDMLink 112.1

- But is unfortunately not supported in standalone environments of Creo Parametric:

- This is due to the fact that there is no notion of "Dependency Tracing" for things happening in Windows

- Hence the reason why:

- if a name changes in the structure of x2.prt (containing definition of the part family table)

- It cannot be propagated AUTOMATICALLY to the structure of x2.asm file (containing definition of the assembly family table calling part instance)

- Current limitation in standalone sessions is officially documented in article 63735 (behavior changed a bit in latest Creo versions, but limitation remains effective due to cause persisting and summarized above)

- PTC provides a tool to do the required replacements in Assembly Family Table using the capability >Tools >Reconfigure Assembly Components >Replace with Family Table Instance

- This capability is illustrated in second attached movie

Hope this helps to have a better understanding of what happens behind the scene, and how to proceed from now on to ensure semi-automatic (semi, because requires anyway manual actions) maintenance of Assembly Family Tables in the scope of Creo Parametric Standalone Sessions.

Regards,

Serge

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Serge

Wow! That was more in depth than I expected, thanks. Would you be willing to look at the original problem that lead to needing this name in family table to automatically update? I am still having issues with that.

MT_WashPA

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

First @sacquarone thank you for participating in this discussion; it's good to see PTC expert on the forum.

So I wanted to take the opportunity here and in the related discussion (Cutout in assembly does not update correctly in family table members) to point out to you some bugs which perhaps have been solved but they sure seem to be there in Creo 4 software.

First issue is that the new-style boolean operations do not behave like the old "component operations -> cut out" type features.

Namely, the old style assembly cutouts seem to work without the need to specify the external reference in the affected parts of the parent assembly.

The new boolean operations require that the part has that reference model column (in order to specify what assembly instance should be used for the definition of the boolean cutout feature). I do think that the latter is the proper method of defining such configurations.

Second issue is related to renaming objects. And you addressed what happens when parts are renamed, and I think that you demonstrated how the assembly family table will be updated even when not in session - when using Windchill. But this is about renaming the instances of the parent assembly.

Because when is done, the ref.model column in the family table of the constituent part is not updated with the new name of the ref. model assembly.

Another bug is that "Switch External References to Instances" for some reason fails to create the required family table with the ref. model column.

But it sure seems to me that the "Switch External References to Instances" function works on my Creo 4 system to update the parts family table.

Hopefully these screenshots demonstrate the strange behaviours:

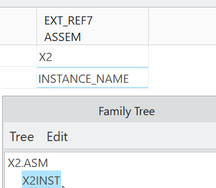

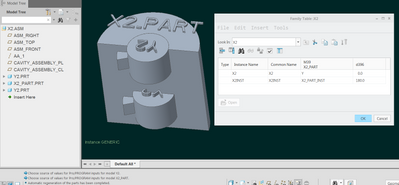

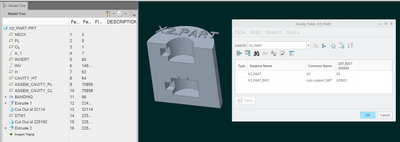

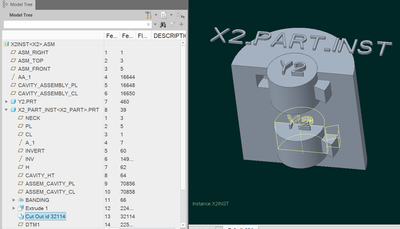

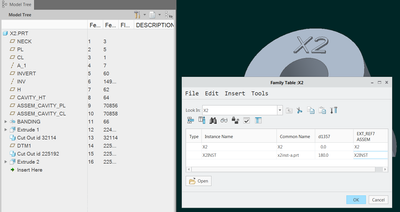

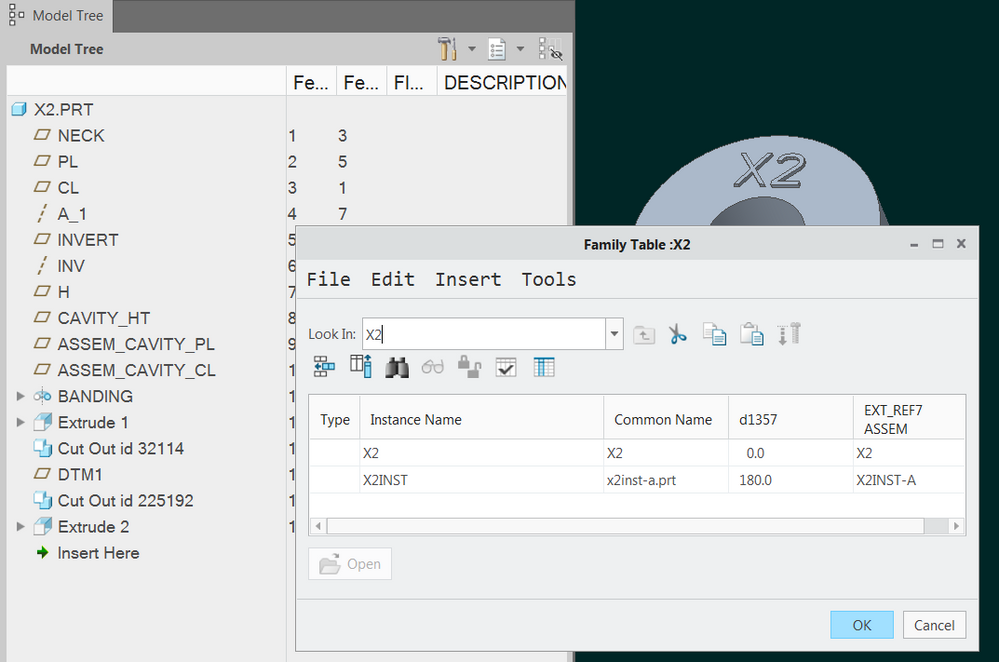

1) Models from PTC_help.7z provided by OP were modified to create this state:

Assembly X2.asm and its family table:

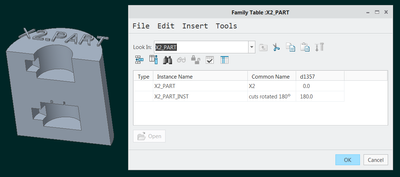

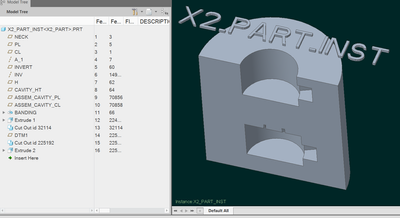

x2_part.prt family table:

Note old style cut-out is at the bottom of the part and new style boolean cut is at the top of it.

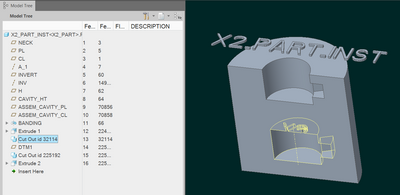

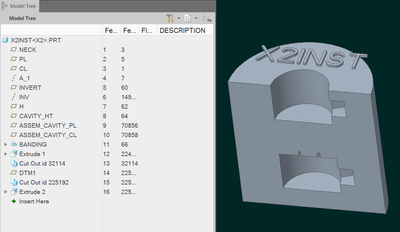

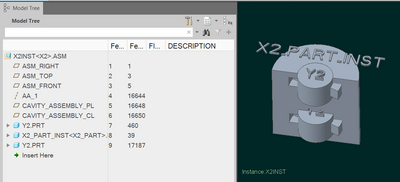

x2_part_inst.prt in the assembly instance x2inst.asm:

Note neither cutout in the X2_part_inst.prt follows the actual placement of component Y2.prt...

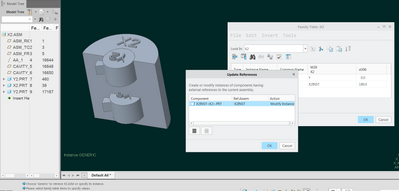

2) After using the "Switch External References to Instances" function in X2.ASM family table:

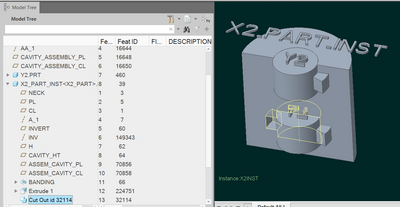

Note ref.model column specifying the assembly instance has been added to the x2_part.prt

Looking at the x2_part_inst reveals something strange:

(that is kind of weird - the old-style cutout does not follow the placement of Y2.prt)

3) Let's delete the ext. ref column in X2_PART family table and add the column that drives the orientation of the plane ASSEM_CAVITY_PL (feature 9) and see what happens:

(that is also weird - both style cutouts work now...)

Actually, that's not right. Closing everything, erasing memory and reopening the model shows the original problem:

Old style cutout works, new style cutout does not...

Well, I think having that 180° angle being switched both in the assembly and in the part has something to do with this confusion, but anyway...

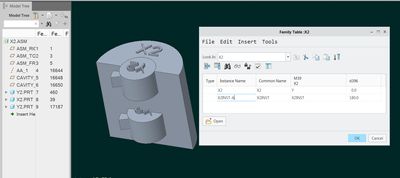

4) Let's use the "Switch References to Instances" to add the ext. ref column to the x2_part in order to "fix" the issue:

It worked...

However, if I open the original data set from PTC_help.7z, delete the ext.ref column from X2.prt family table, regenerate and save everything and then reopen the files, I'll arrive in this situation:

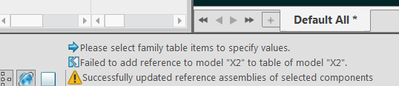

Now trying to fix this by adding the ext.ref column via "Switch References to Instances" does not work:

X2.prt family table is unchanged and I have this error message:

Anyway, that demonstrates the strangeness of the behaviour of the cutouts in Creo.

Lastly, we can manually add the ext.ref column to the x2.prt family table and it all works again:

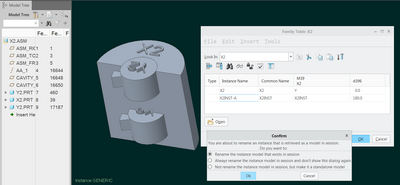

However, now if I rename the instance X2INST.ASM, then the family table of X2.PRT will not update:

(that needs to say X2INST-A)

Okay, then if I open the family table of X2.ASM and use "Switch References to Instances":

then the family table of X2.prt is updated:

In conclusion, it seems that managing parts and assemblies in Creo can be very frustrating, especially when family tables are involved.

It should also be noted that situations where things seem to work until next time the models are re-opened can be encountered, which is troubling.

I hope you can use this message to point out issues in the software to the developers.

Also, the structure of the data set provided by the OP seems complicated and it would be great if the proper techniques for arriving at solution to the business need would be demonstrated to the rest of the forum users.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello @MT_WashPA

Thanks a lot for your for your kind message 🙂

Hello @pausob

Wow! Impressive summary. I'm afraid to not have the bandwith to answer to all your points. Later on, if you want to ensure a tracability of exchanges and report some of your above questions to PTC TS, we suggest you to open a case to PTC Technical Support.

Regarding one of your points above, please let me maybe just clarify why I said yesterday :

Switch External References to Instances capability CREATES (and DOES NOT UPDATE) the Family Tree of Affected Component whose instance name was changed.

Better than a long and wordy explanation, I attach a new movie which will hopefully clarify this, and is aligned with what we document in our Help Center.

As a general rule (which may help to understand some of the things discussed above), when you "rename" an instance in Family Table Editor, please consider that system:

- Does not use a real logic of "rename" (like what it happens when done in the scope of PLM environments)

- But behaves as if existing Instance was Deleted and a New one would have been Created, which is very different

Above rule is not a regression, as it applies to ALL Creo Parametric (and formerly Pro/ENGINEER) versions, since the introduction of the first versions of Pro/ENGINEER

For the rest of your questions (Related to your findings when investigating original Cutout in assembly does not update correctly in family table members post), I think it's better to pursue exchanges in this specific post, in order to avoid mixing exchanges in this topic originally dedicated to the question: "how to handle rename process of family table part instances called later in a family table assembly instances".

I cannot commit I'll be able to have some activities on the old post, but I'll try to find some time to look deeper at it later.

Regards,

Serge

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Well, your last video still shows you renaming the X2.prt part, which is not the issue here; it's about what happens when renaming an assembly instance in the assembly X2.ASM...

But I too don't really want to spend more time on this and will end by saying that these conversations only reinforced my general rule: avoid use of family tables.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you for your efforts. No idea what video you are referring to. But

no matter. Do you have a suggestion for an alternative to family tables?

I design mould equipment for the glass container industry. Two part

moulds with common exterior shape and sizes. Typically the only

differences are features on the partingline and if the cavity is for a

non-round bottle each half is unique (hence the needed 180°rotation). This

family table method has worked like magic for years but have recently

experienced failure of the cutout when the cavity becomes complex.

Recreation of the cutout in a newer version reduces the failure rate but

then the previously used rotation method does not work reliably.

Again thank you for your efforts.

MT_WashPA