Community Tip - Learn all about PTC Community Badges. Engage with PTC and see how many you can earn! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- SWEEP OR SURFACE MODELLING(Tongue and groove joint...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

SWEEP OR SURFACE MODELLING(Tongue and groove joint)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

SWEEP OR SURFACE MODELLING(Tongue and groove joint)

Hi,

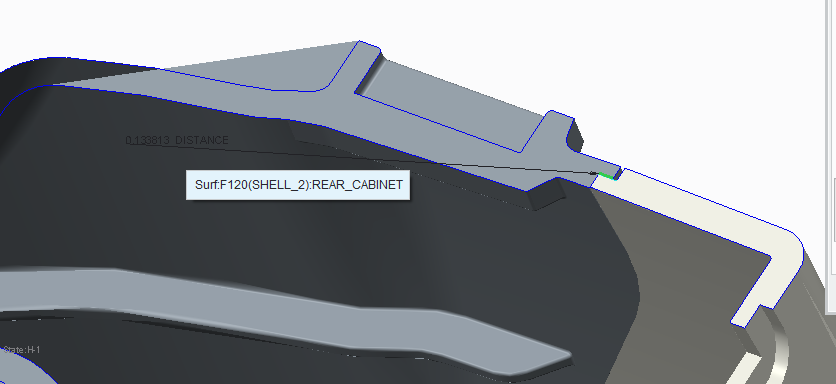

I'd like to know how to give tongue and groove fit on plastic parts. I've attached a assembly where you can find the parts with tongue and groove fit. The matter is I've created tongue and groove fit in the cabinets but the fit is not as expecting the groove after it butts the other cabinet should have 0.5mm clearance all around which i have but as you can see from the

picture there is a 0.13mm gap between the parts and in some places and i can't have it can anyone please tell how to do it. In the front cabinet i created tongue using Sweep command and in Rear cabinet i created groove using surface offset and solidify because sweep wasn't able to create groove all over. can anyone advise how to do this.

Thank you @

@

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

Assembly Design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Babu,

In your Assembly there is just his image but not the parts.

So we can not do much.

Kind regards.

Denis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Denis,

In the image I've shown the assembled view but I've attached the assembled file pls see the attachment

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Babu,

Yes, but in the Assembly there's not room.

In the file asm0001.asm.1 into Creo we see an image at the time of

the open but it is empty.

Kind regards.

Denis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Denis,

I'm sorry Denis i forgot to attach the parts. NO PROBLEM this time i have attached the zipped file please go through it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I haven't looked at your files, but generally I'd suggest to use the same method for each parts to get compatible results. For simple part lines, sweeps can work well, but you need to mind the type of sweep and make sure it's the same for each part. For complex parting lines, building or cutting away using offset surfaces generally works well.