Community Tip - If community subscription notifications are filling up your inbox you can set up a daily digest and get all your notifications in a single email. X

- Community

- Creo+ and Creo Parametric

- Analysis

- Re: Not converge for prescribed translation

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Not converge for prescribed translation

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Not converge for prescribed translation

Not converge for prescribed translation

Here are the errors that I faced

** Warning: Convergence was not obtained because the maximum

polynomial order of 4 was reached.

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I impose the deflection "f" to close the gap, but the analysis not converged

Can you help me?

Thank you

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I impose the deflection "f" to close the gap, but the analysis not converged

Can you help me?

Thank you

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This looks like it might have a singularity requiring isolate for exclusion. Can you give a few more details on how you setup the enforced displacement? Is it on a point or edge? Is the model 2D? How does this relate to an actual physical test? Could you actually do this in a test lab? If so how would that be done?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The enforced displacement is a section, it a 3d model I have not a phisical test

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

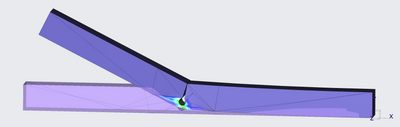

Suggested technique to enforce the gap closed as you indicate. Use at own risk.

This a technique when enforcing rotation on 3D because 3D elements only have translational DOF. (degrees of freedom)

Keep in mind strain results are logarithmic for large displacement.

https://support.ptc.com/help/creo/creo_pma/r10.0/usascii/index.html#page/simulate/simulate/lg_deform_strainmeas.html

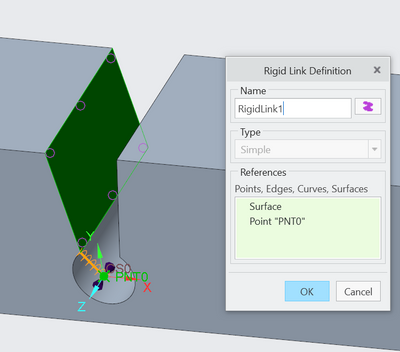

1. Coordinate system at center of rotation

2. Point on coordinate system

3. rigid link from moving section to Point

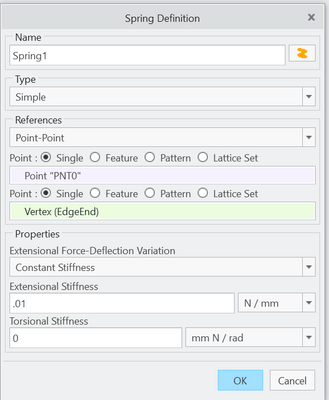

4. Simple 2 point spring from Point to anywhere. (very low stiffness)

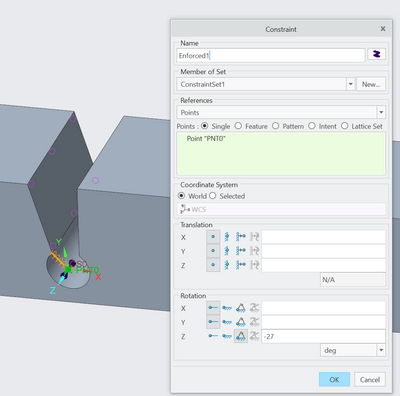

5. Constraint on the point to rotate the section the amount needed to close the gap. (may need to adjust the amount, radians or degrees)

6. Enable large displacements and enough steps to allow convergence (I show 21 steps, or 5% increments)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How is this the solution?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It would seem your multi-pass (MPA) analysis settings were selected to converge on a measure with the maximum polynomial set to 4 and the convergence percentage identified was not met. I would recommend running the SPA (Single-Pass Adaptive) first to see how it solves, and then if you require convergence to be demonstrated, re-run your MPA study but increase the maximum polynomial order to 7 or 8 (even 9 since it looks like a fairly simple, single part analysis).

SPA analysis is actually very robust, and should solve more quickly as well. Unless you require demonstration of convergence, SPA would be the approach to use more often.

I hope this helps!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello,

Couple of suggestion :

- Run analysis in Multi-Pass Adaptive analysis

- Increase maximum polynomial order

- Try by changing the model accuracy

- Increase the mesh density of the model and more elements in high stress gradient regions in this model.

- Adding some mesh controls.

- Change the AutoGEM settings so that the face and edges minimum angles must be larger.