Community Tip - Want the oppurtunity to discuss enhancements to PTC products? Join a working group! X

- Community

- Creo+ and Creo Parametric

- Analysis

- "Cannot process highlighted contacting surfaces"

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

"Cannot process highlighted contacting surfaces"

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

"Cannot process highlighted contacting surfaces"

I’m trying to run an FEA on a fixed support beam, I replaced all the bolts with “intelligent fasteners”. I keep getting the “cannot process highlighted contacting surface” error

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Articles:

- "Error in Creo Simulate analysis: "Cannot process highlighted contacting surfaces"": https://www.ptc.com/en/support/article/CS325621

- "Err: "Cannot process highlighted contacting surfaces. Source: Geometry" was returned while run autogem": https://www.ptc.com/en/support/article/CS313559

Discussion - "Contact surface area error": https://community.ptc.com/t5/3D-Part-Assembly-Design/Contact-surface-area-error/m-p/326502

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks so much for replying!

I had already seen the first two posts.

I will try the Refine Model > Beam option, and see what results from it.

Thanks again for replying.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I created the beam (I think correctly), but it didn't seem to help.

Any additional assistance would be appreciated.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

can you make better screenshots?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks so much for replying!

Certainly, I can post better screenshots. Please let me know if you would like more/better still screenshots.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

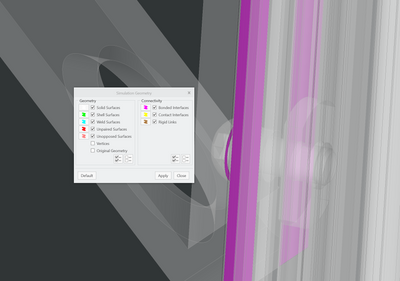

Sorry, man, but you have black model with black edges. There is still 0 visibility on the problematic region. try changin model color to white/light gray. take a screenshot without first part than without the other. Describe problematic region in text and include simulation features applied to them. What kind of interface you are using. Most of the time those are tangential surfaces. But can't prove it from those screenshots.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

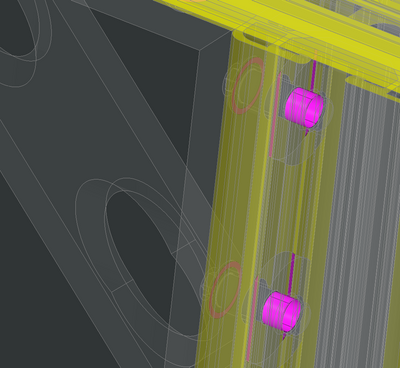

Problem understood.

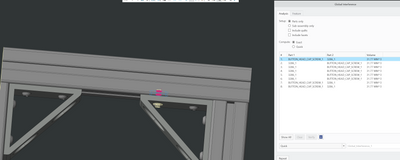

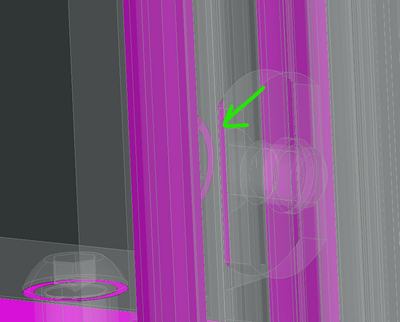

What you are looking at are 3 40mm x 40mm aluminum profiles with 2 heavy-duty (HD) corner brackets holding them together. I am attaching screenshots and a .zip with a SolidWorks assembly (the assembly is imported into CREO). I will work on better screenshots of the actual highlighted surface of the profile.

I thank you for all your assistance.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I am unable to open the cad file for the 40x40 extrusions.

The first thing I noticed was very different part and assembly accuracies. It is best if they are all set to 0.01mm. This could very well be your issue. Make sure coincident surfaces are actually coincident and there are no interferences.

Tools - Tolerance report will show all the tolerances.

I downloaded new 40x40 cad from McMaster Carr.

When I model only the 3 extrusions and corner braces and set the default interface to bonded, the model works great.

I am using Creo 10.0.0.0

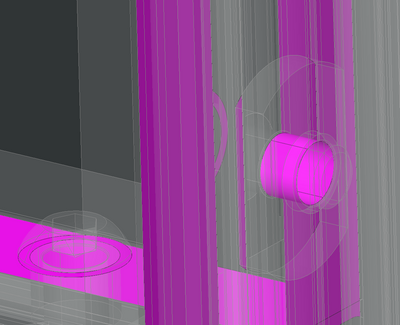

The T-nuts were not in contact with the rails in my model, and they had interference with the bolts.

t-nut moved into contact

Nut sized to match bolt

Of course a more accurate model would have contacts and preloaded bolts, rather than just bonding, but you should walk before you run.

I would probably just have contacts at the brackets and bonded at the bolt/nut as shown below.