- Community

- Creo (Previous to May 2018)

- Creo Modeling Questions

- ___ Daily update. CHEVROLET CAMARO 2010 -STYLE- CL...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

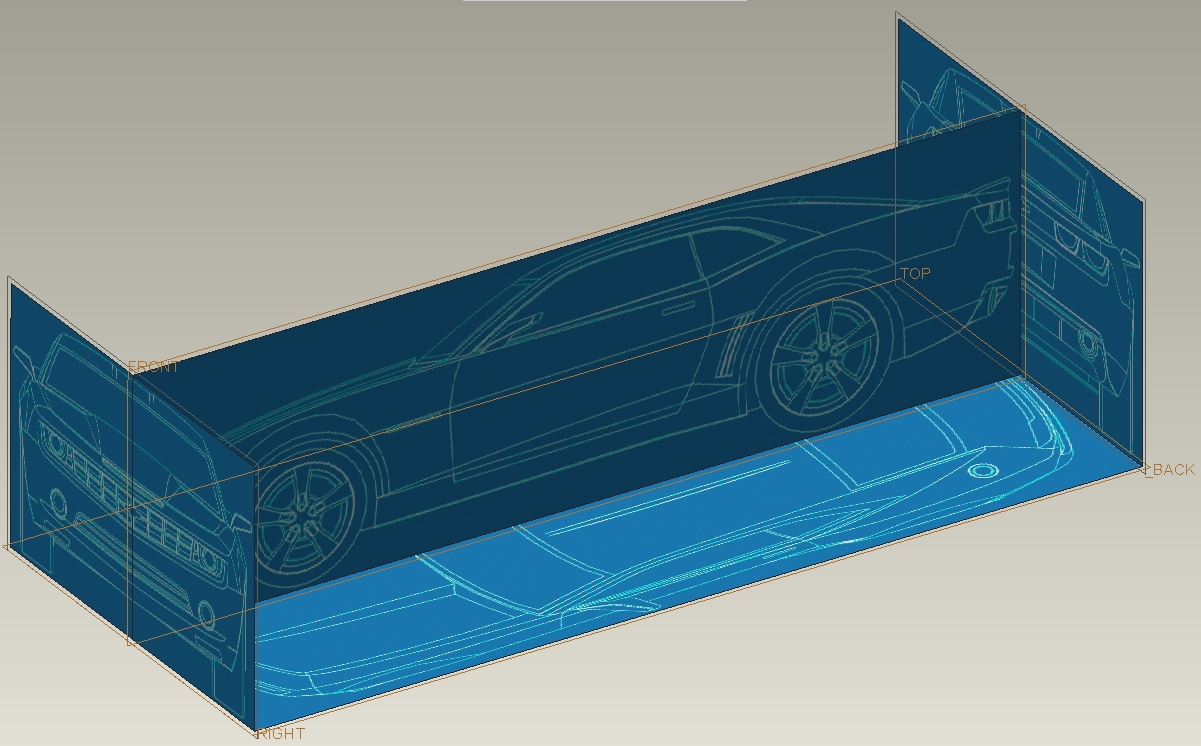

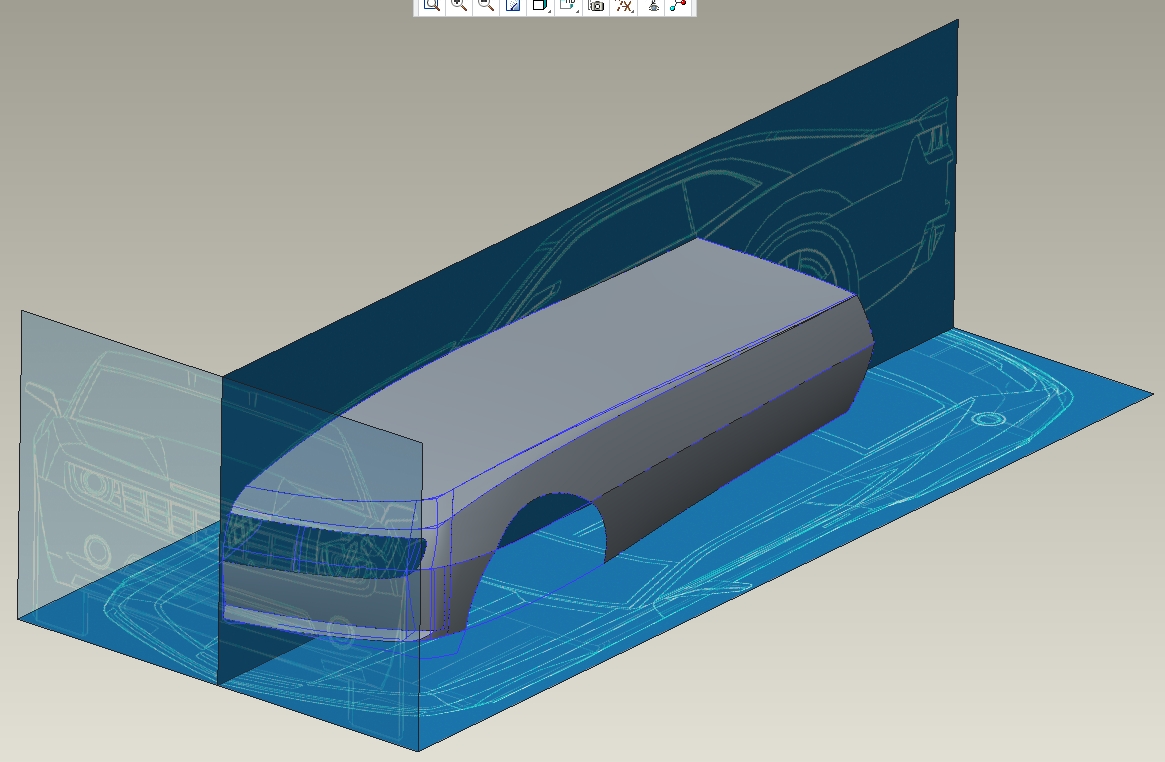

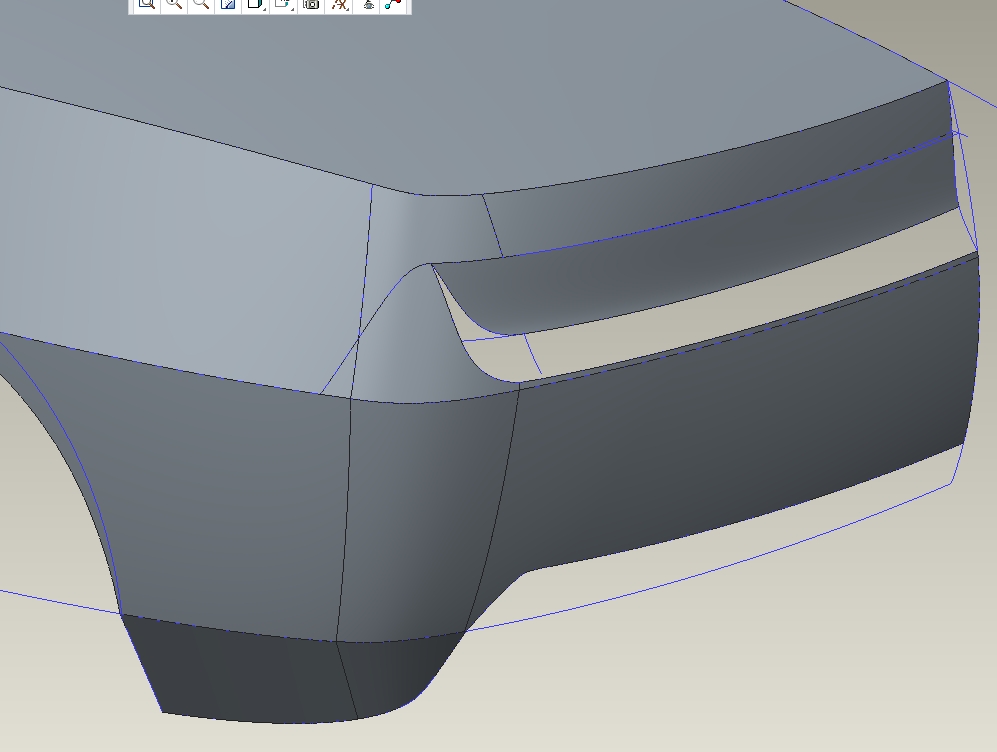

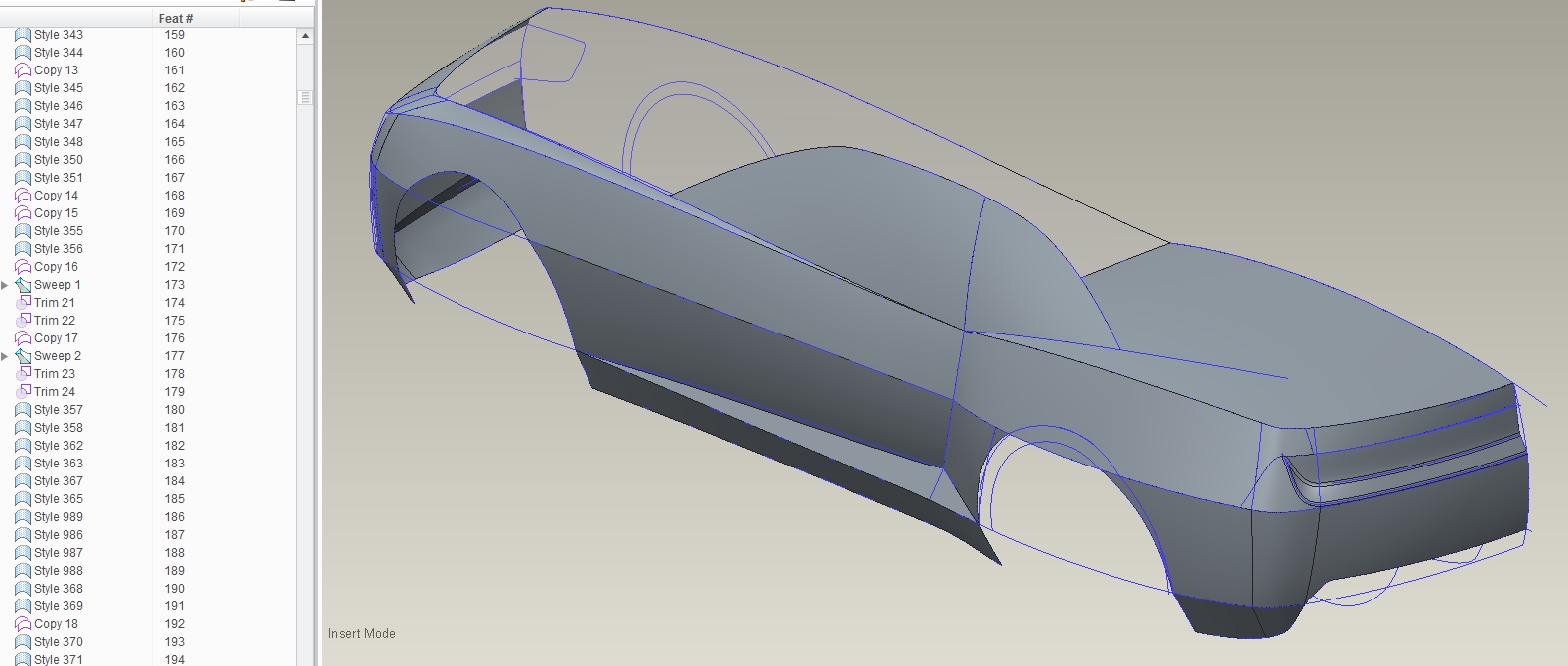

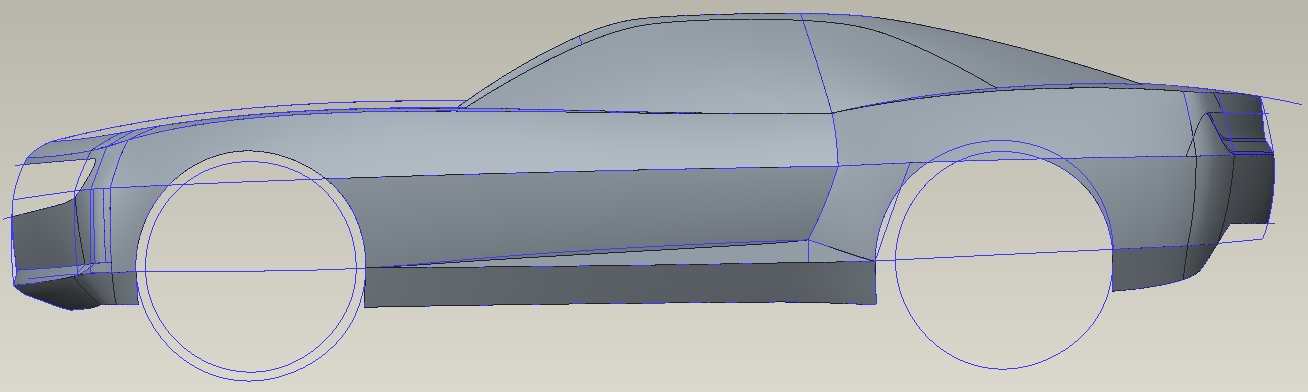

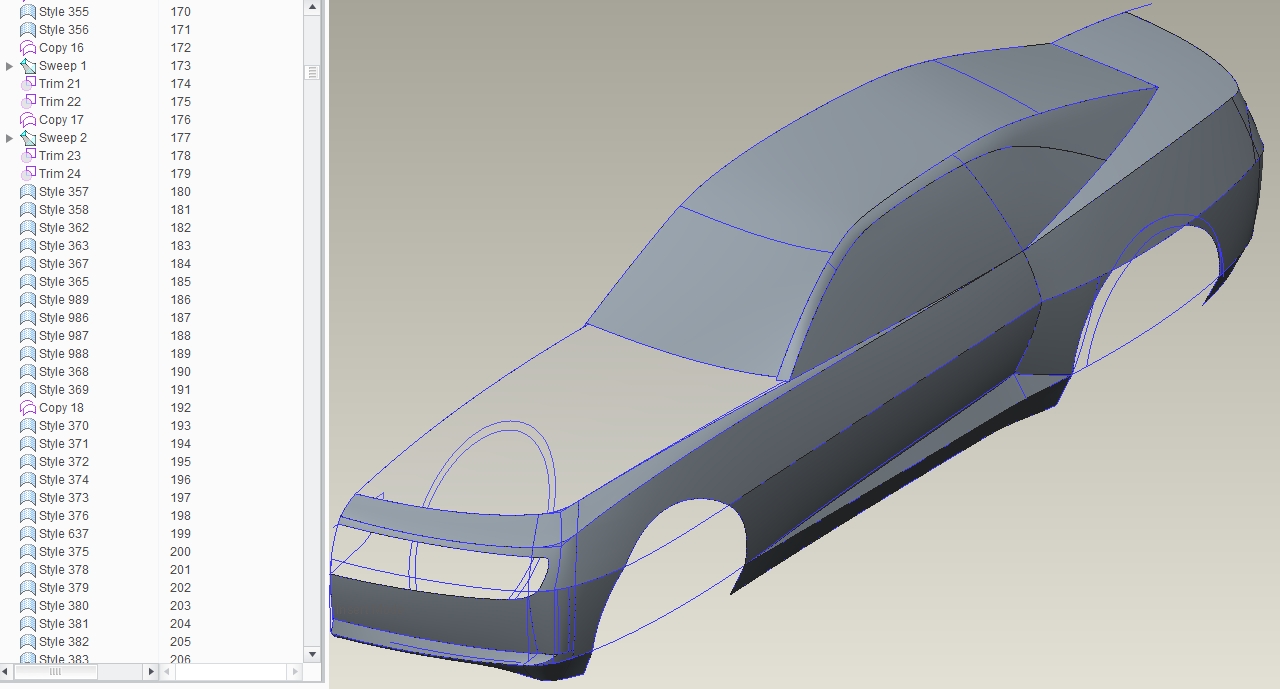

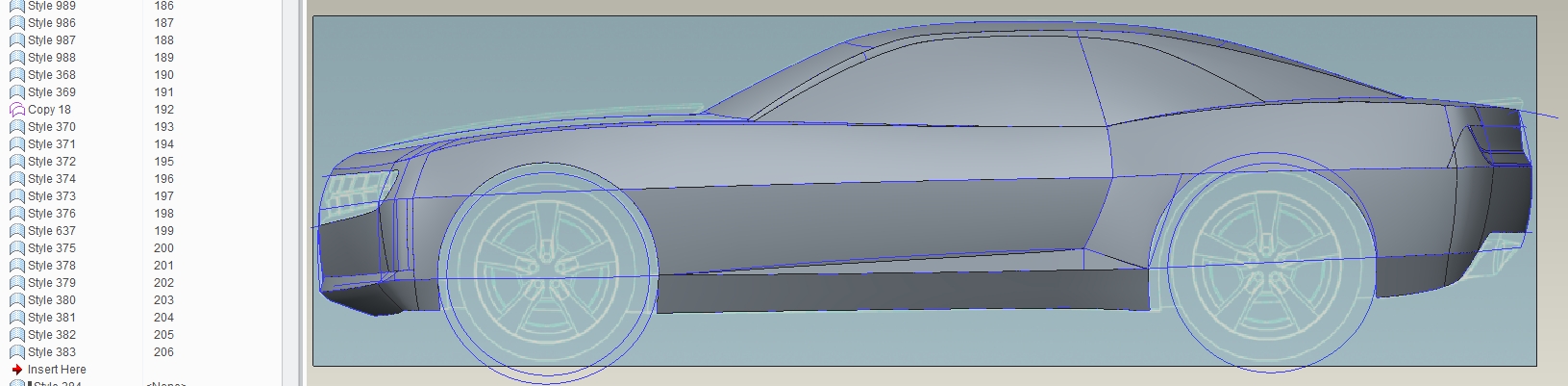

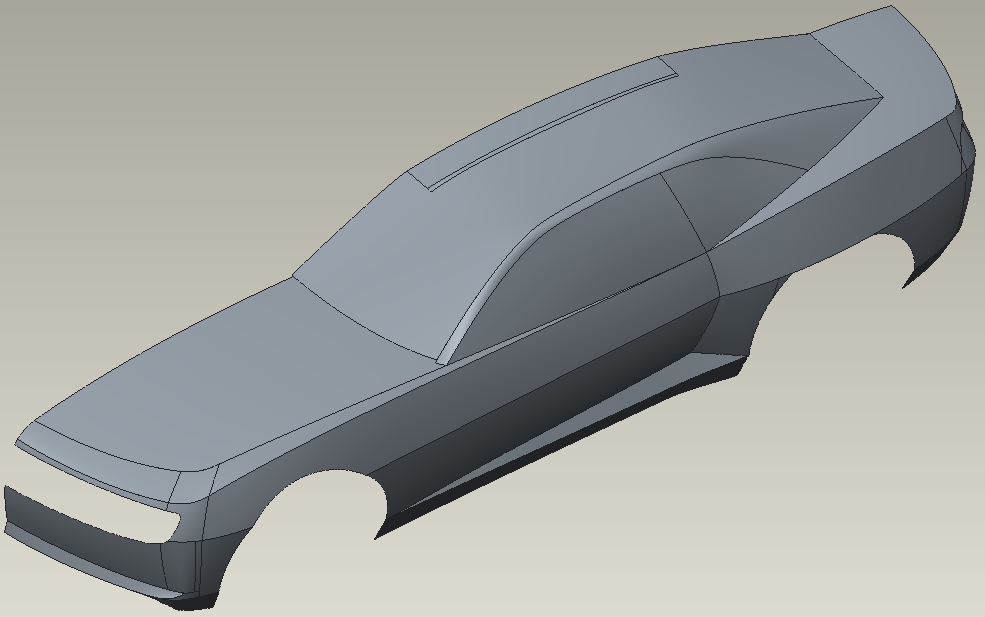

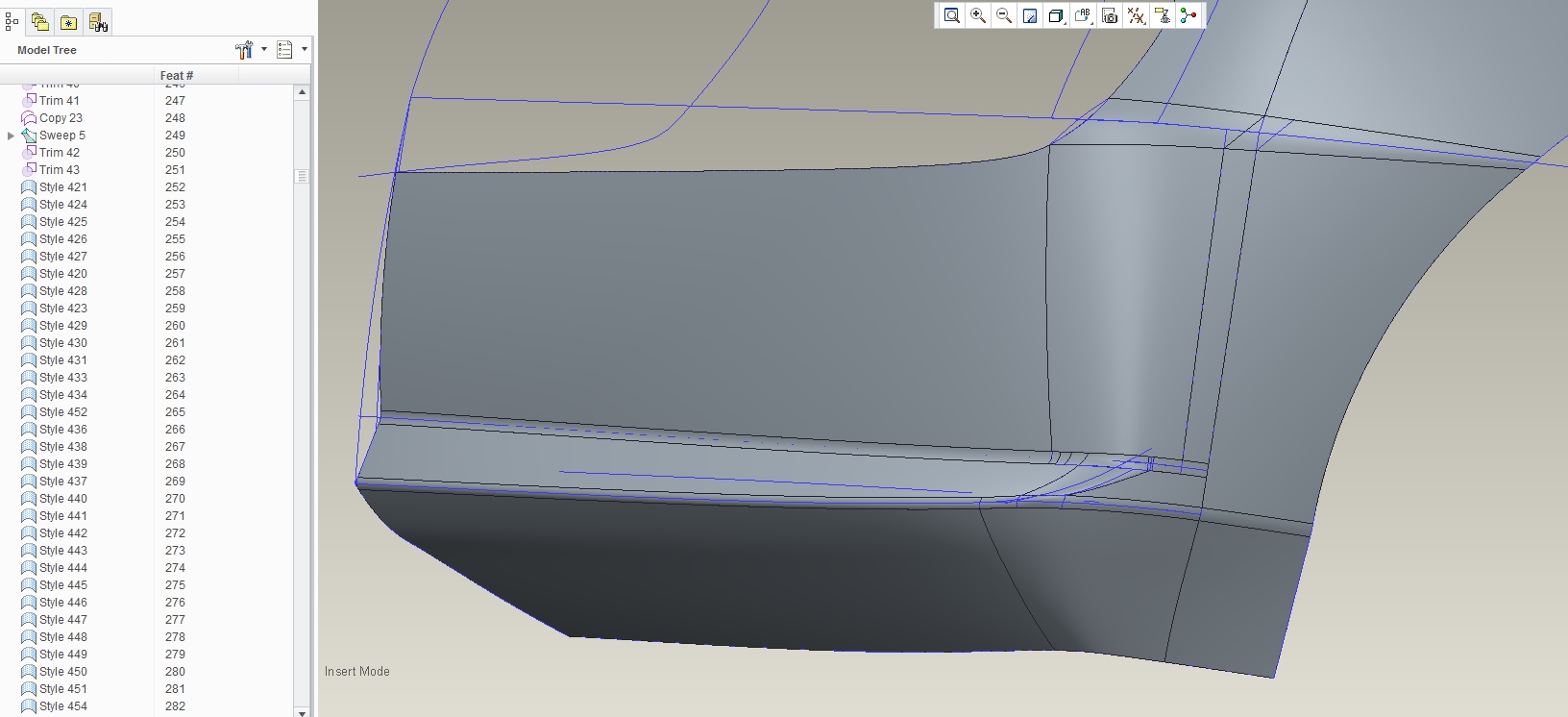

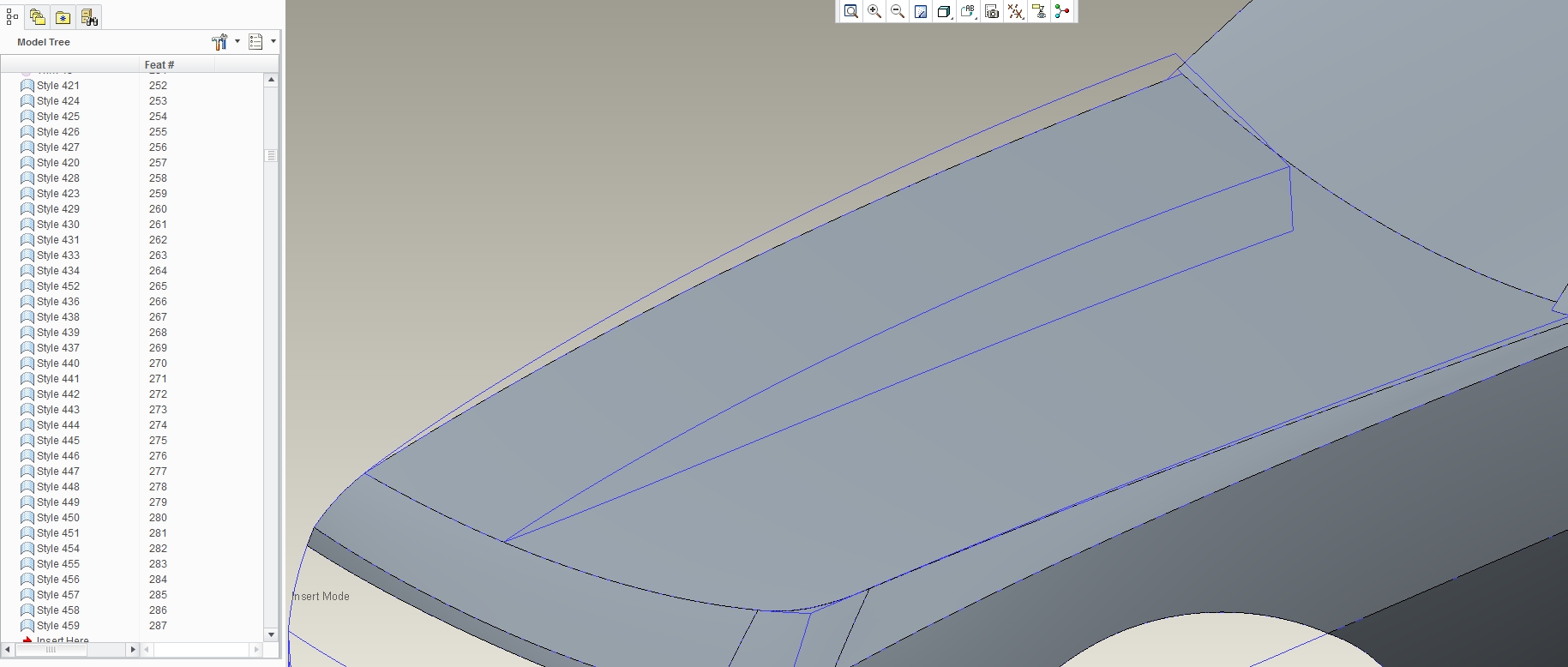

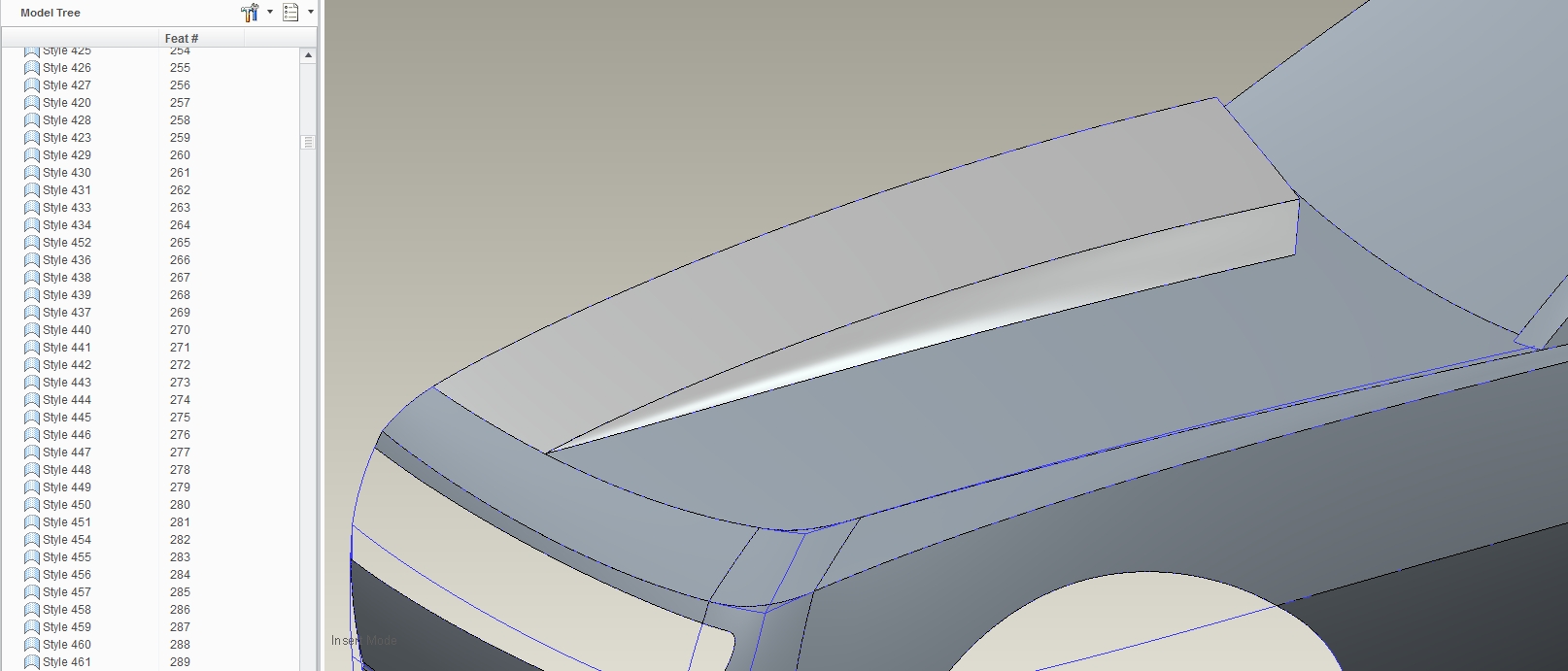

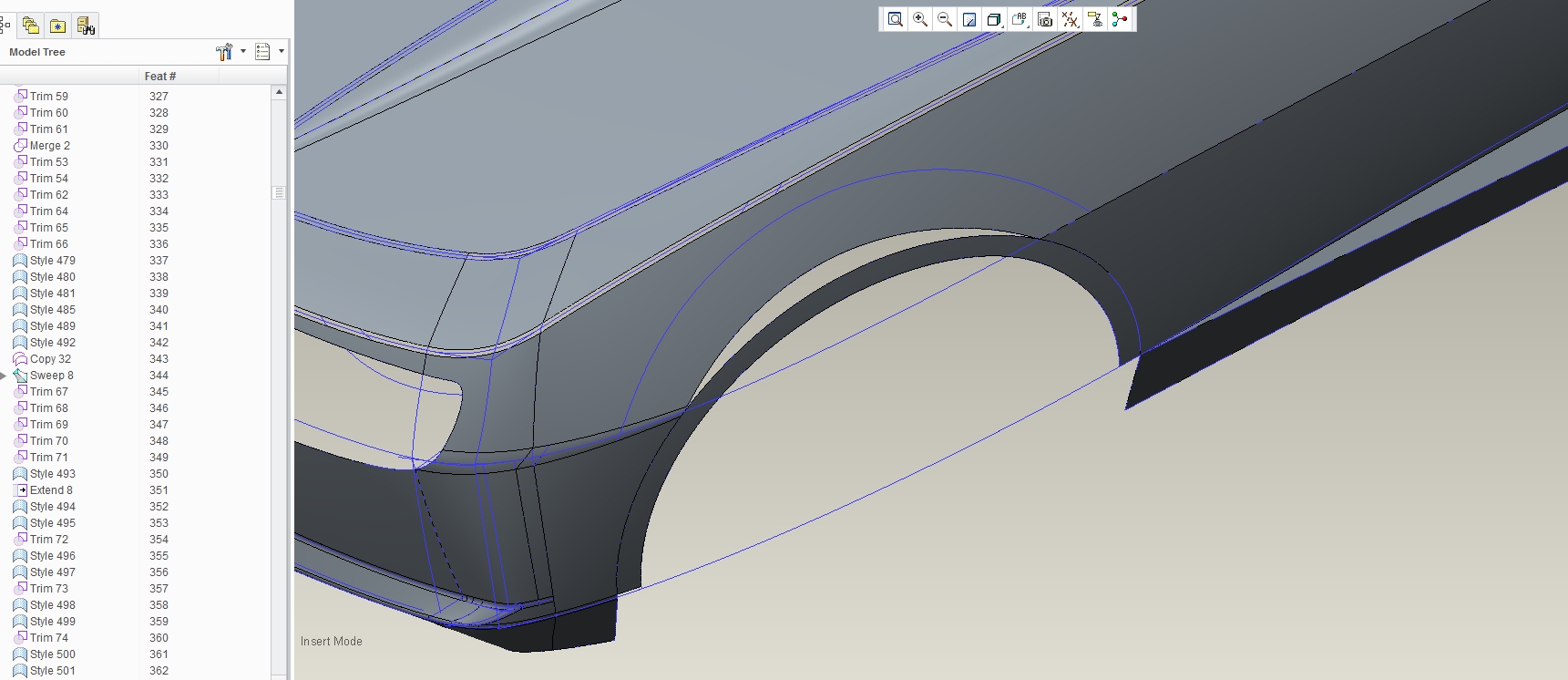

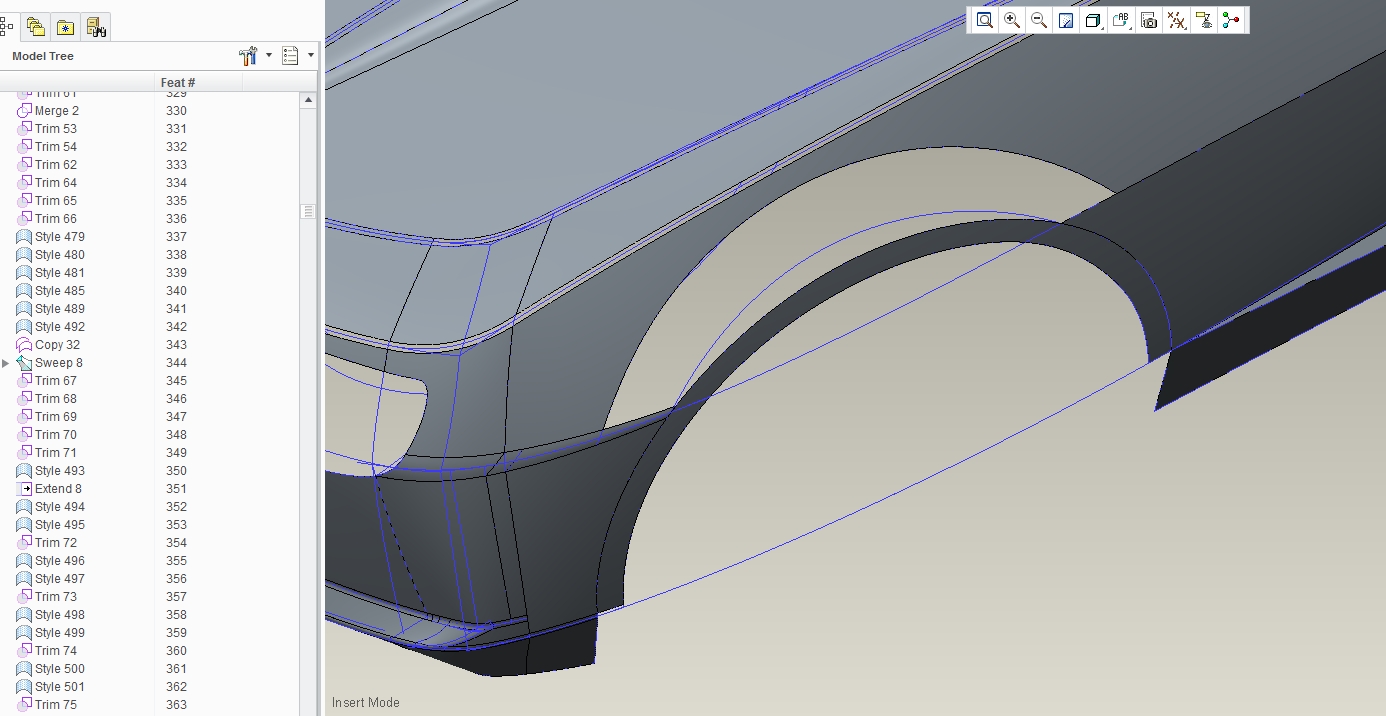

___ Daily update. CHEVROLET CAMARO 2010 -STYLE- CLASS A SURFACES - Working in progress (SPARE TIME)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

___ Daily update. CHEVROLET CAMARO 2010 -STYLE- CLASS A SURFACES - Working in progress (SPARE TIME)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

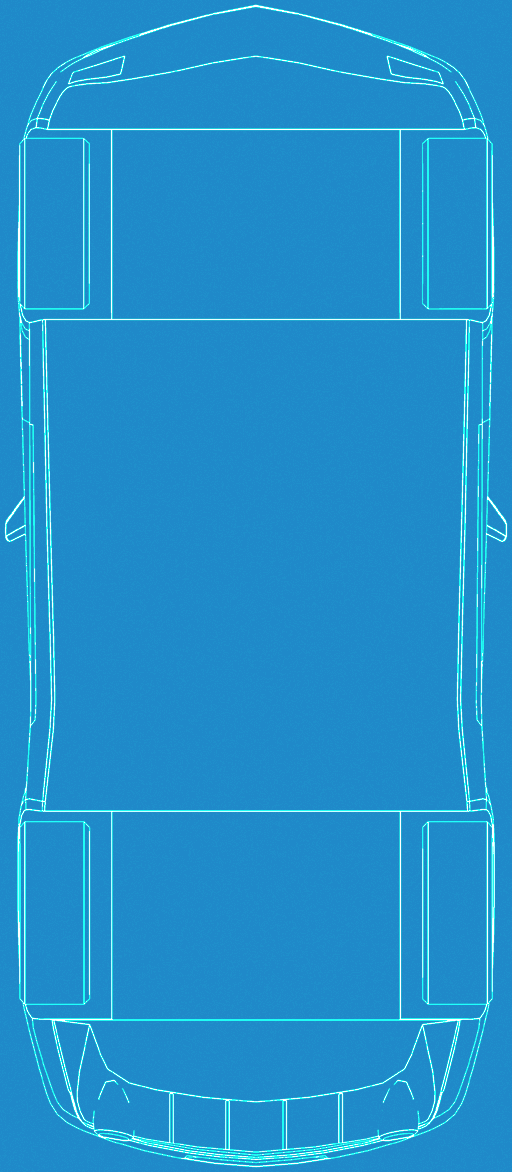

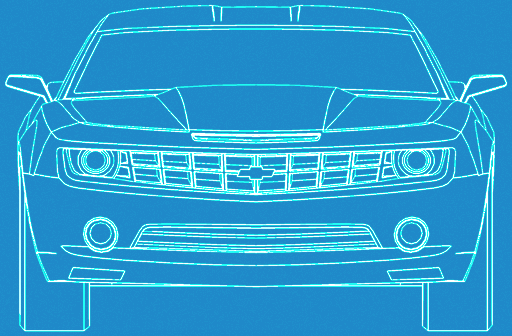

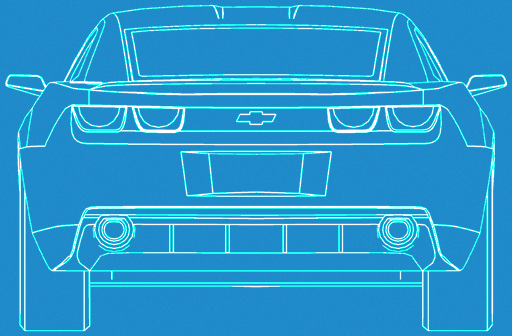

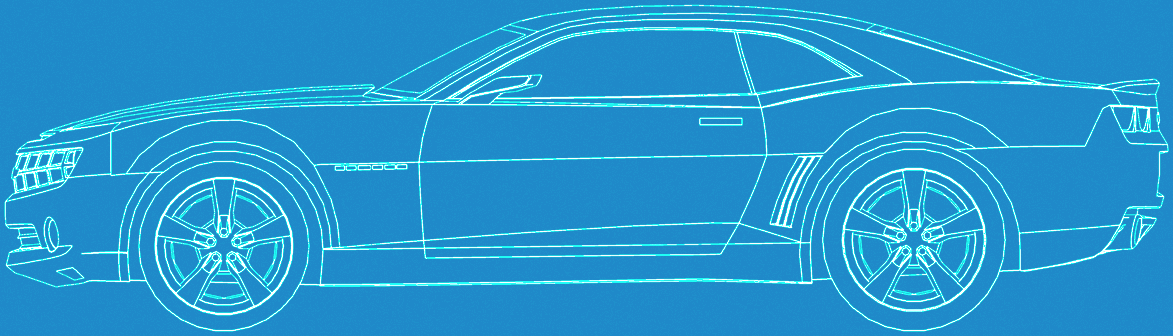

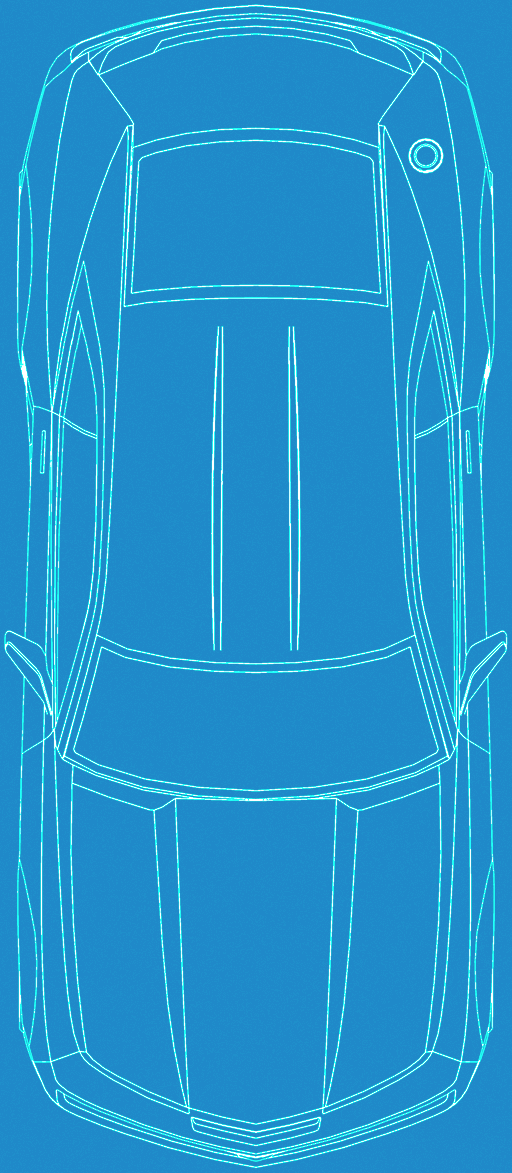

Looks like a fun challenge. So where did you get the line drawings of the 4 views to use as your templates?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Mark!

I don't remember where I found this line drawings... I think it was in kodg-3d.com...

Hug

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

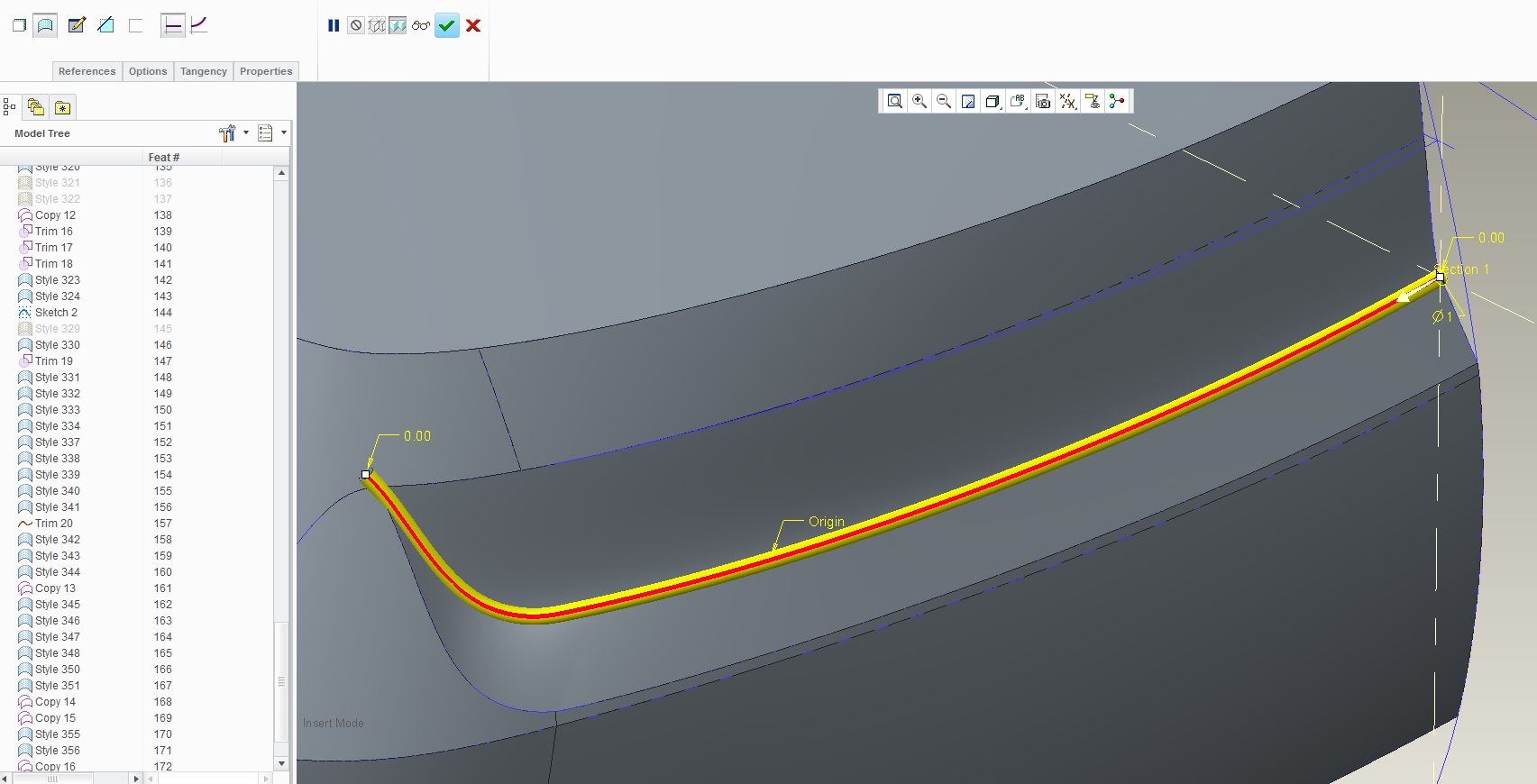

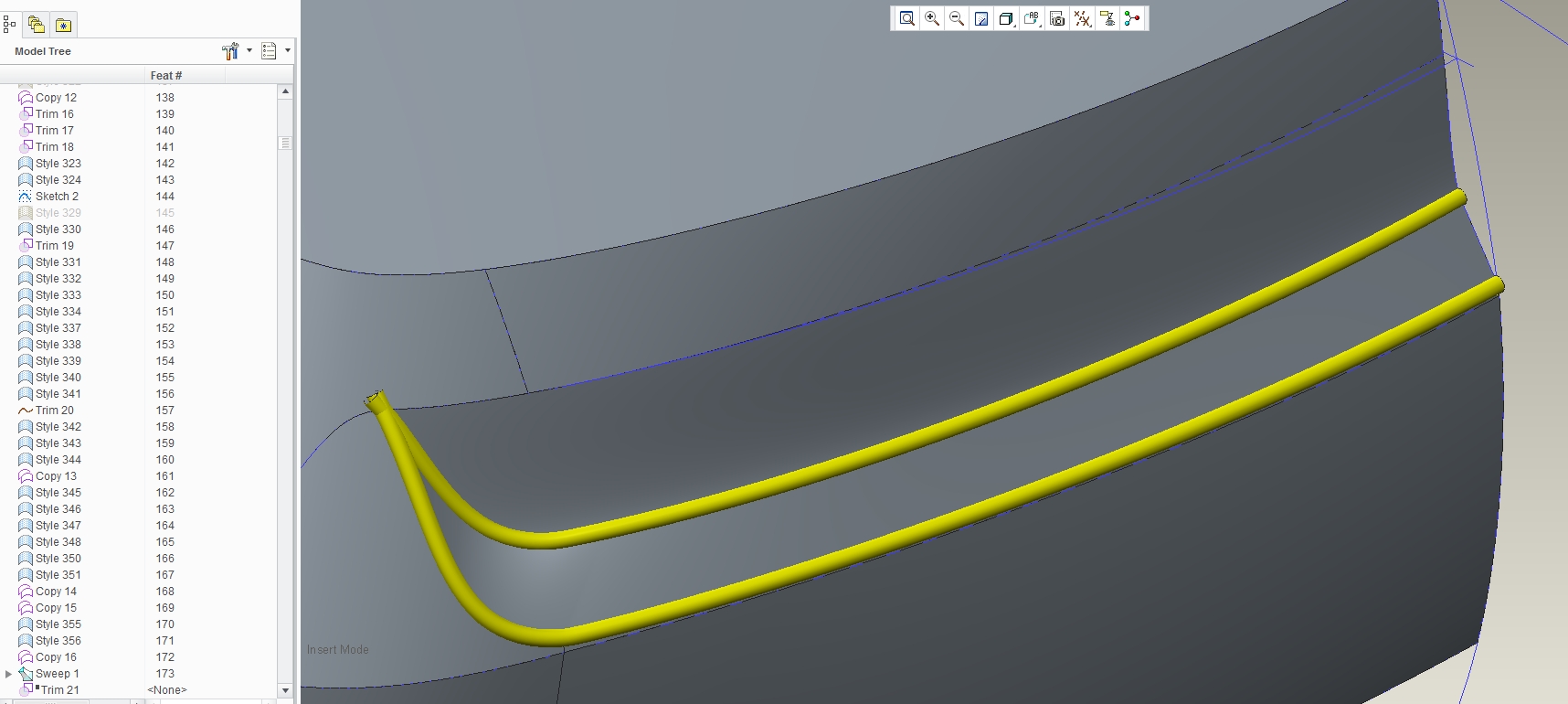

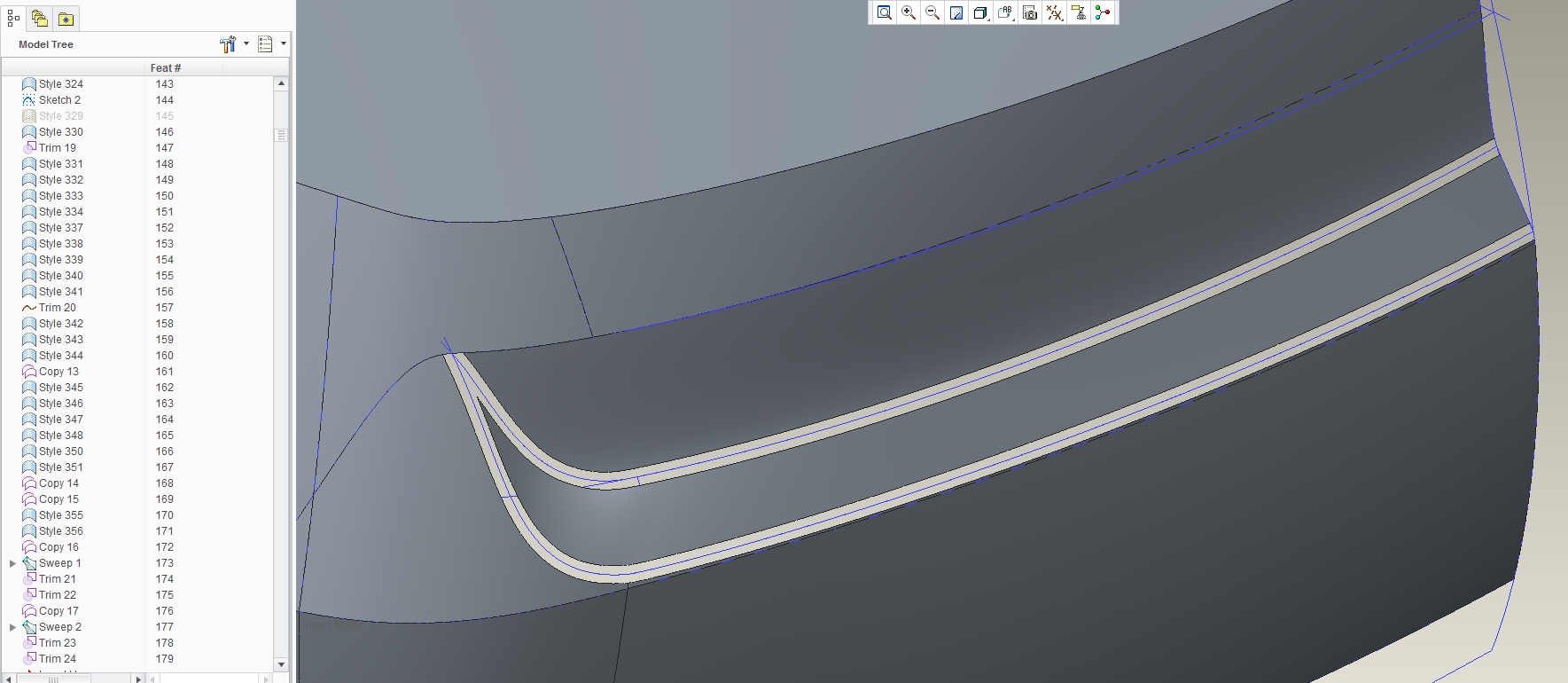

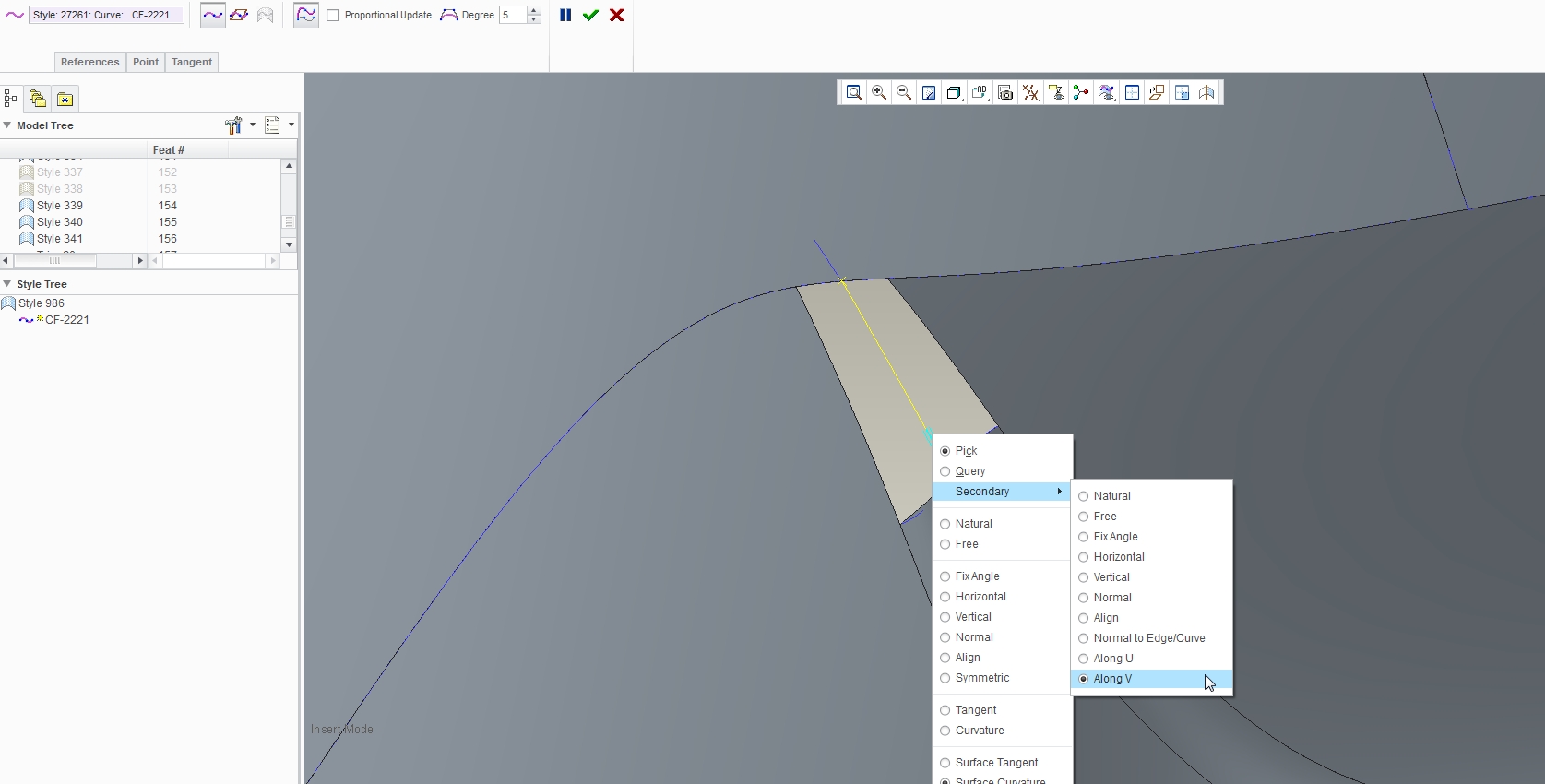

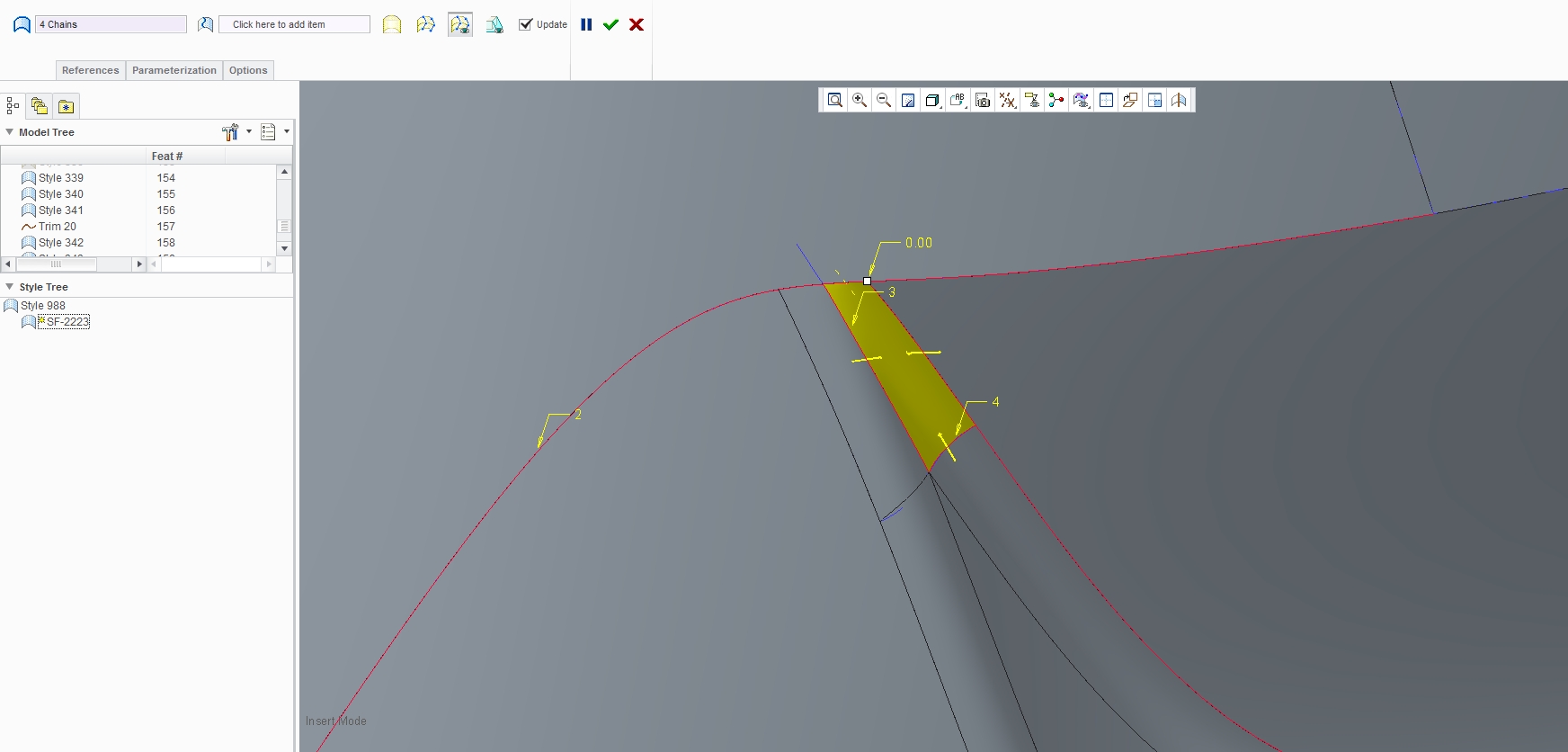

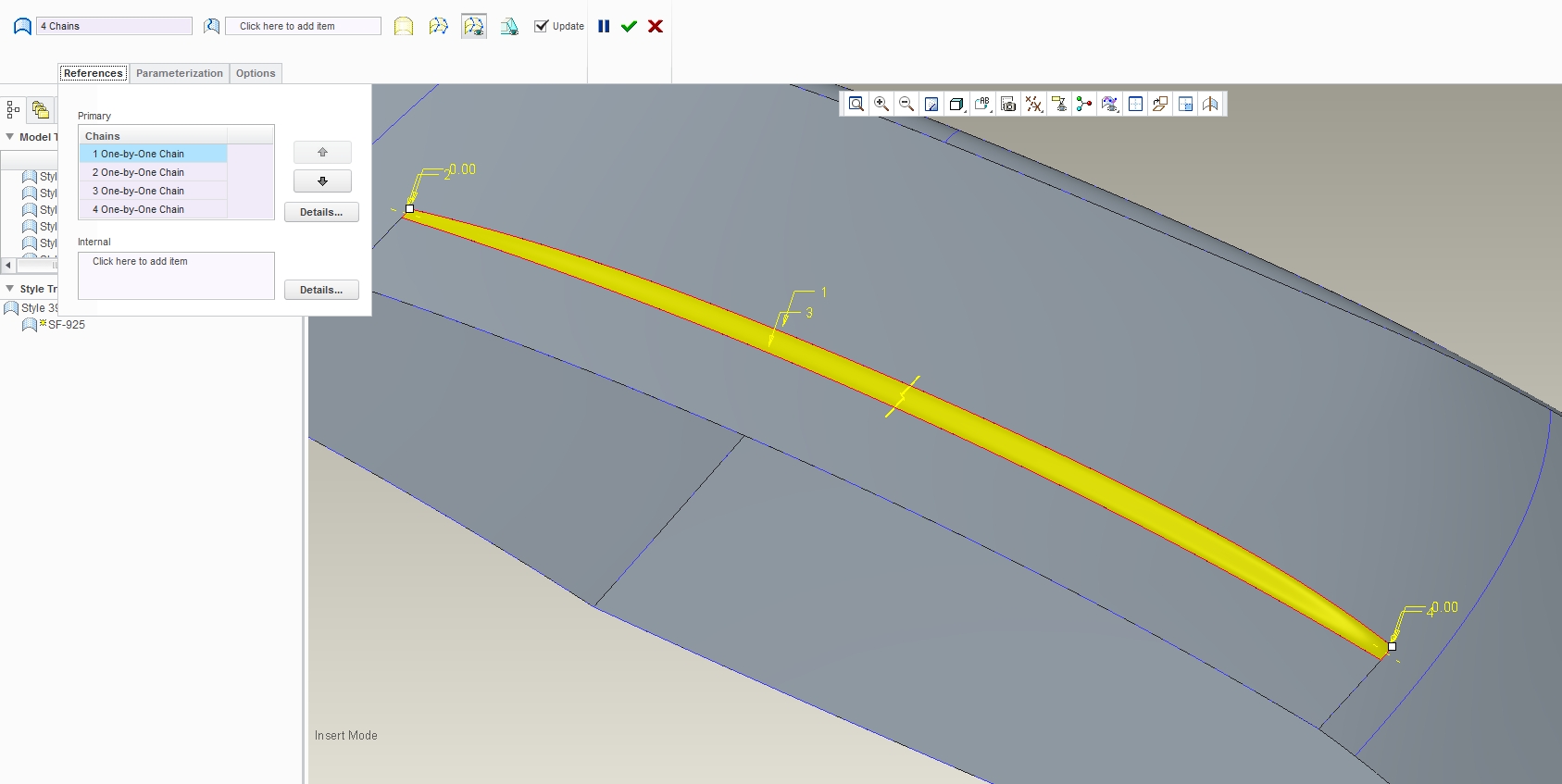

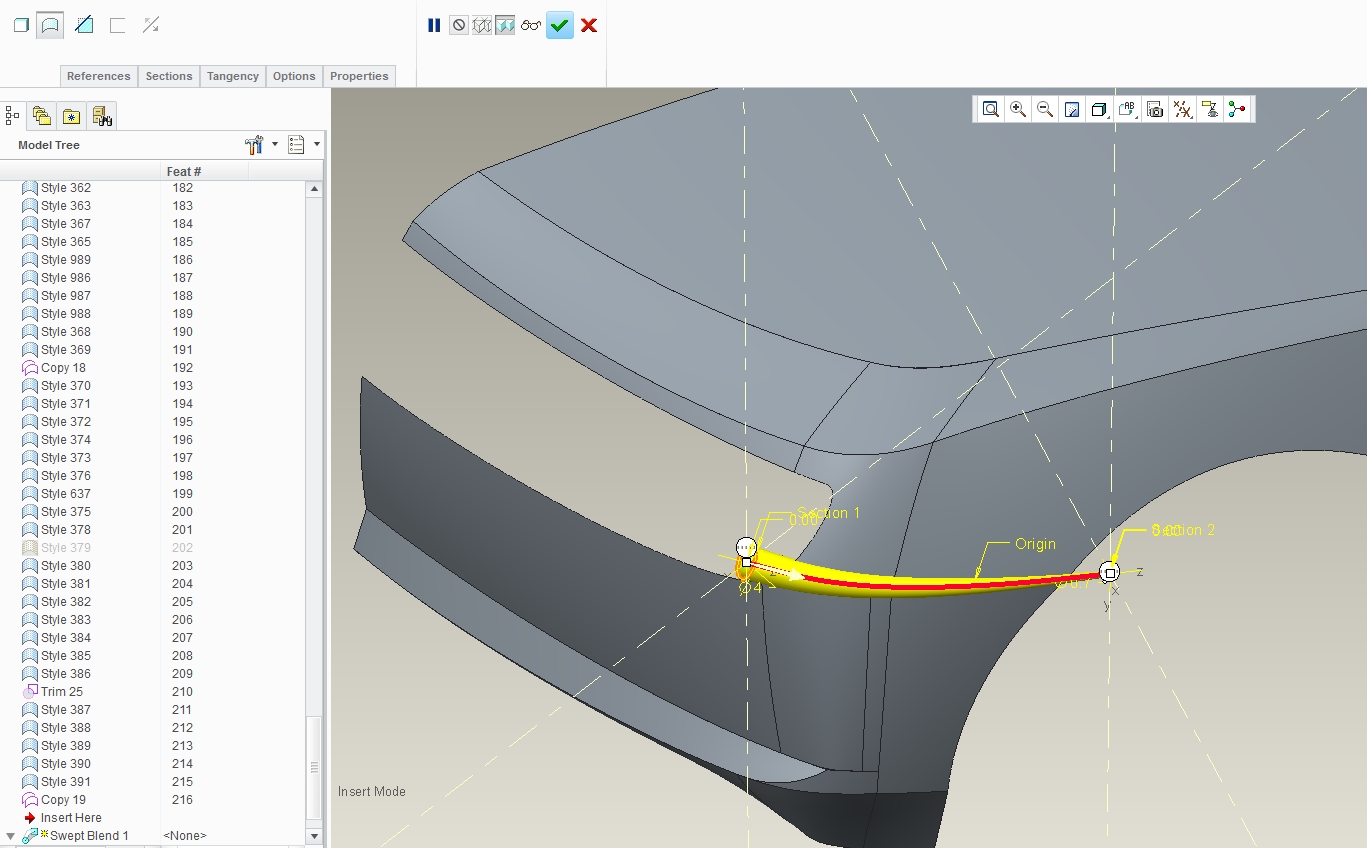

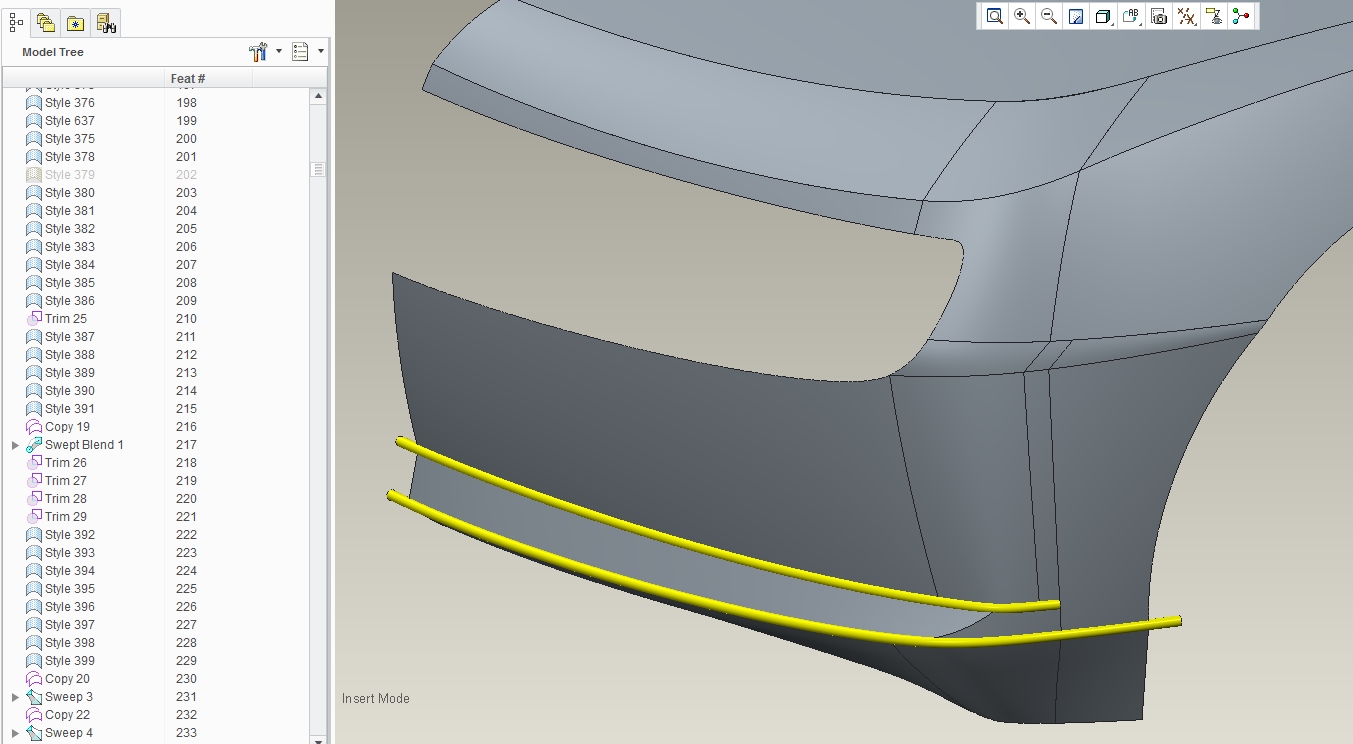

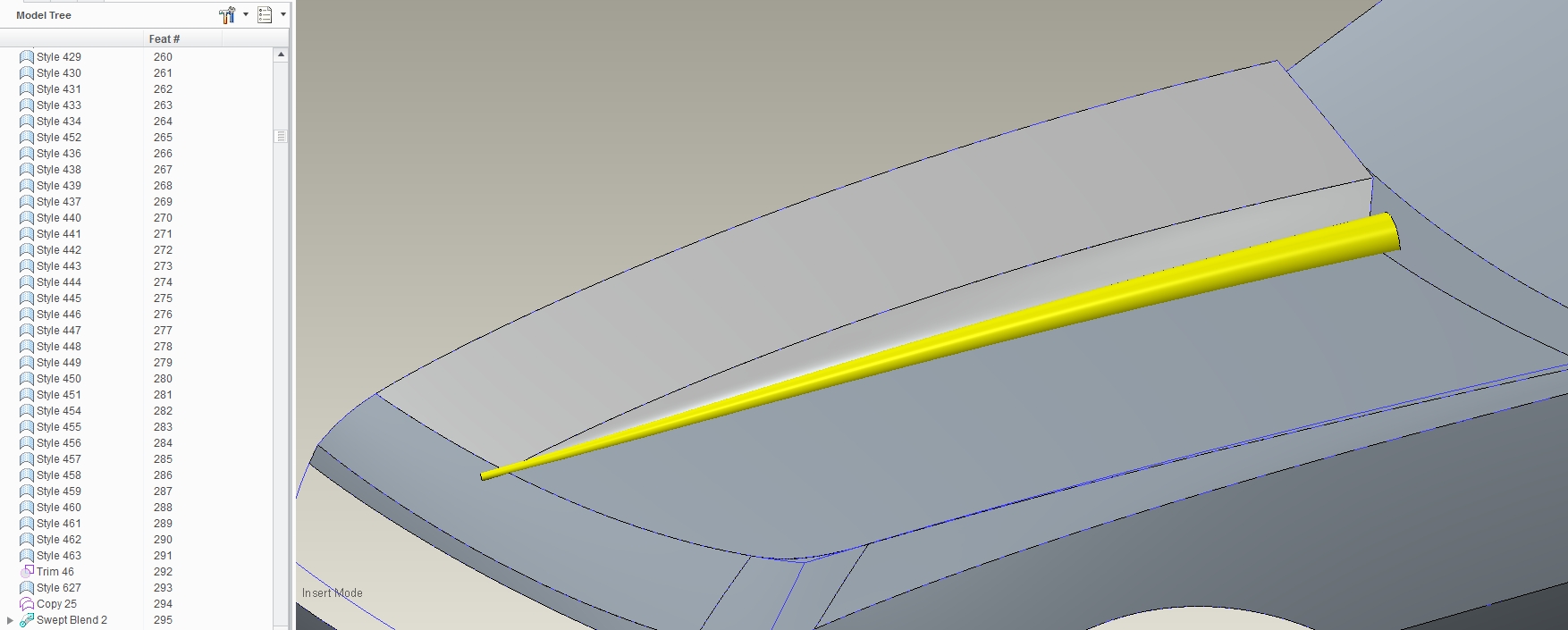

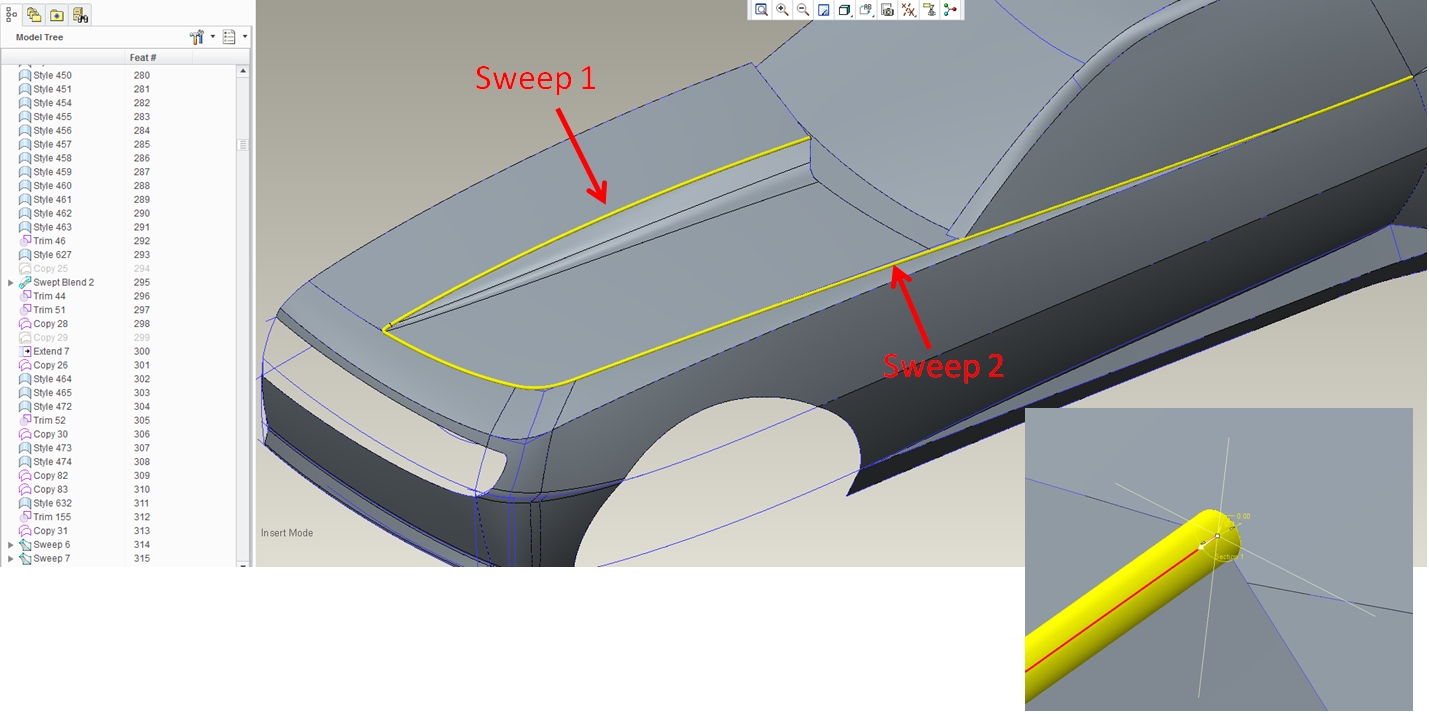

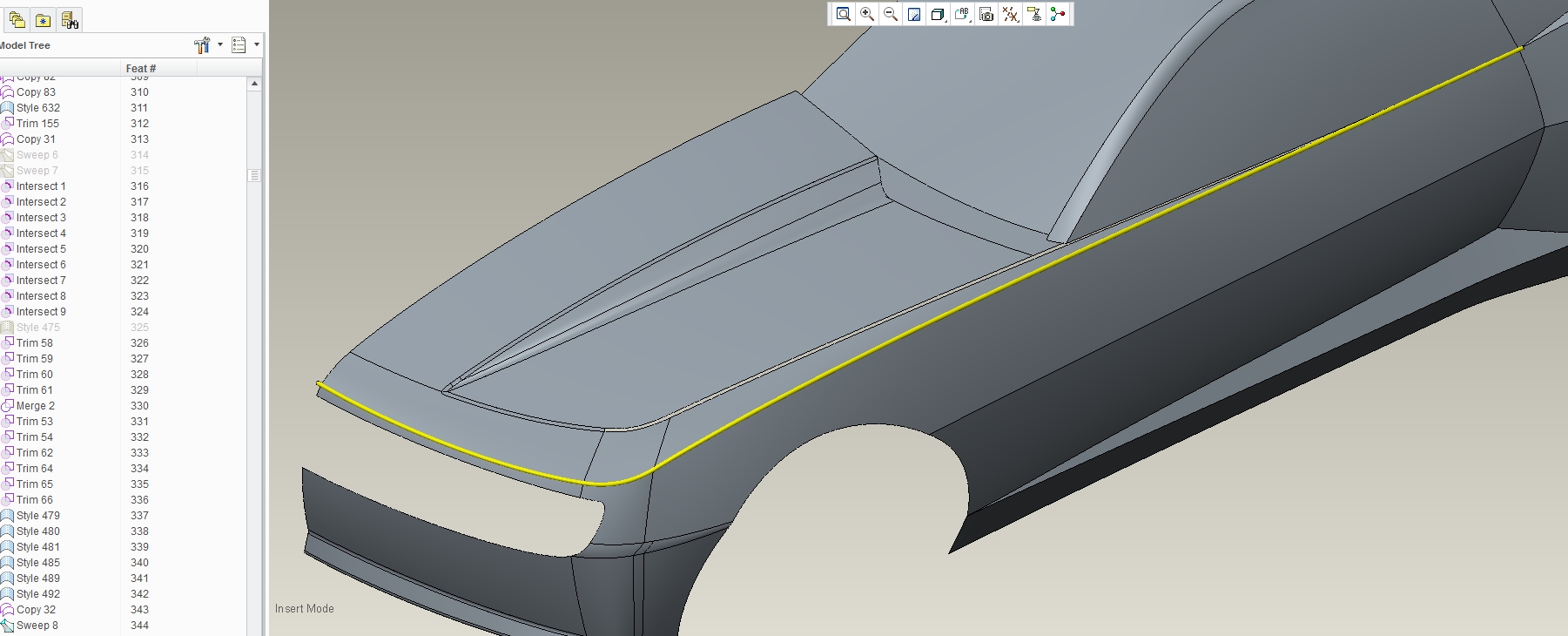

Couple questions. Why are you using Style surfaces? Is it just easier to create or do you get better control of tangencies between surfaces or are you just more comfortable with style surfaces instead of boundary blends or other base surfaces? Also what are the yellow features? I presume these are cuts or trims of these existing surfaces at their intersections? You are cutting these surfaces out to control the radii between them better vs just adding radii? I have never used Style surfaces and have heard from engineers they don't like them when they inherit designs that need down stream designs created. In my product design experience I have been using basic surfaces and boundary blends, merges, extensions, trims, etc when I need complex shapes and geometry for products. I have never needed class A surfaces.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

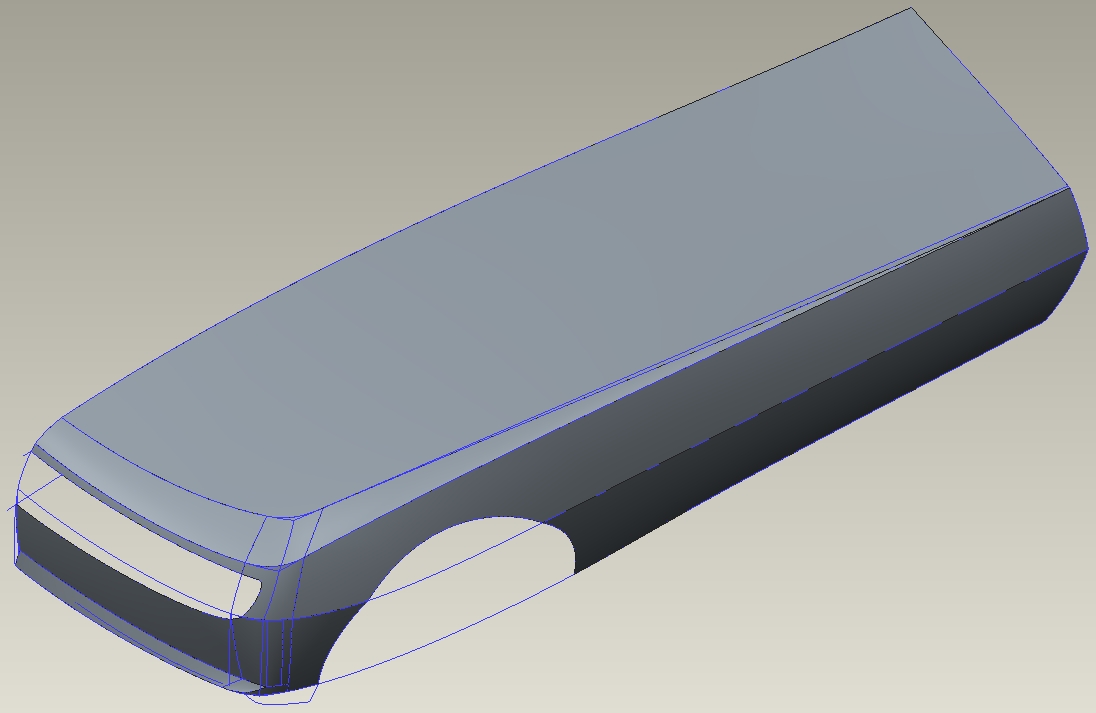

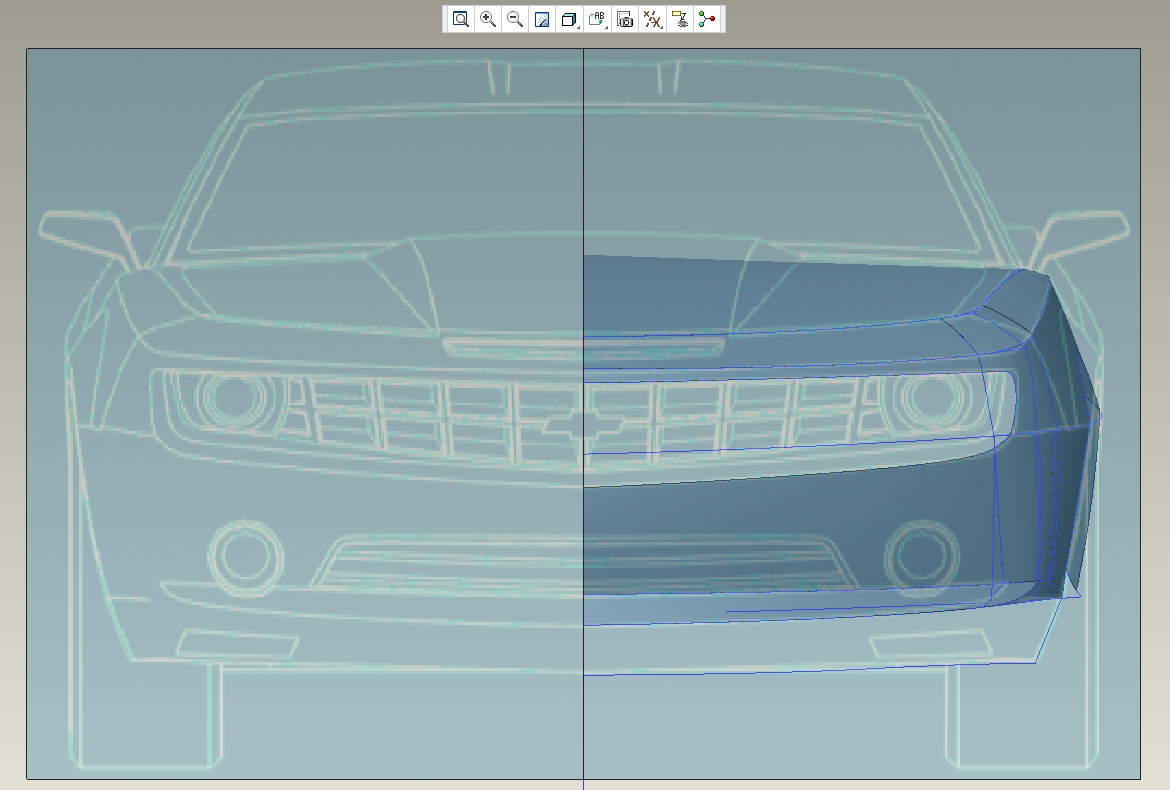

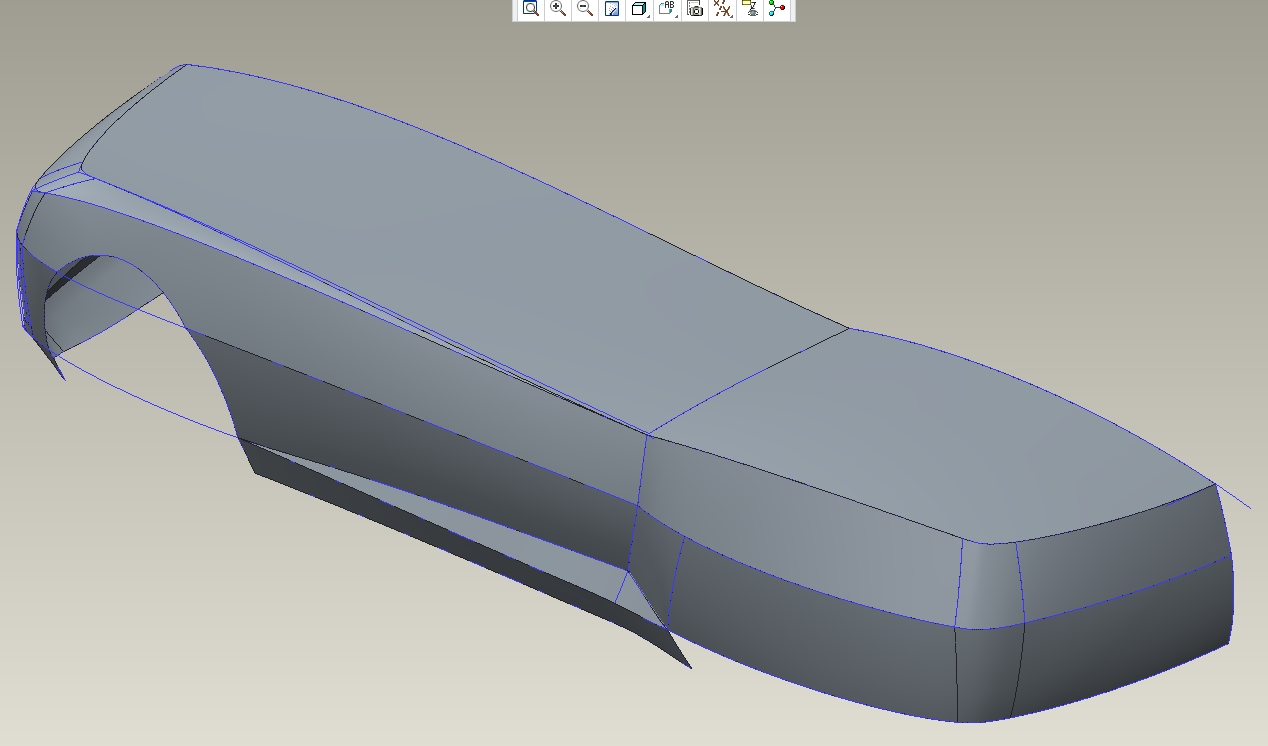

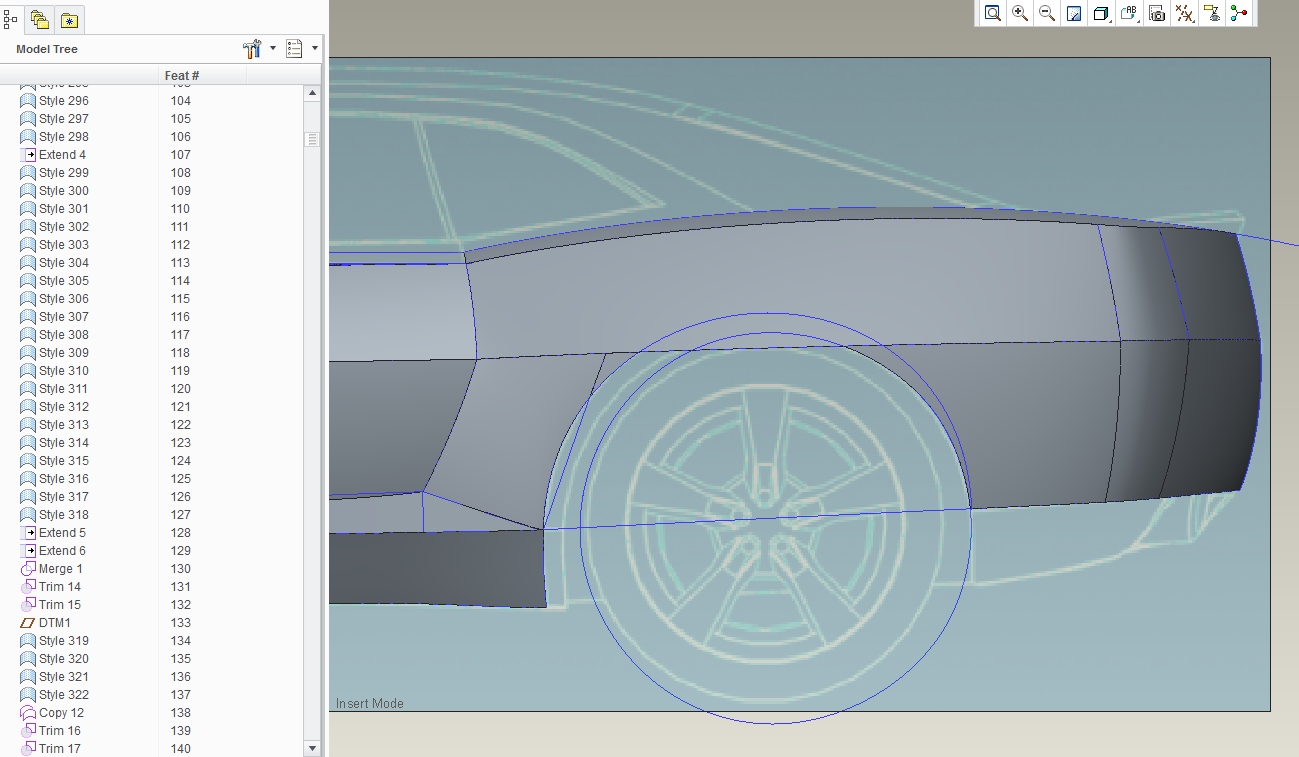

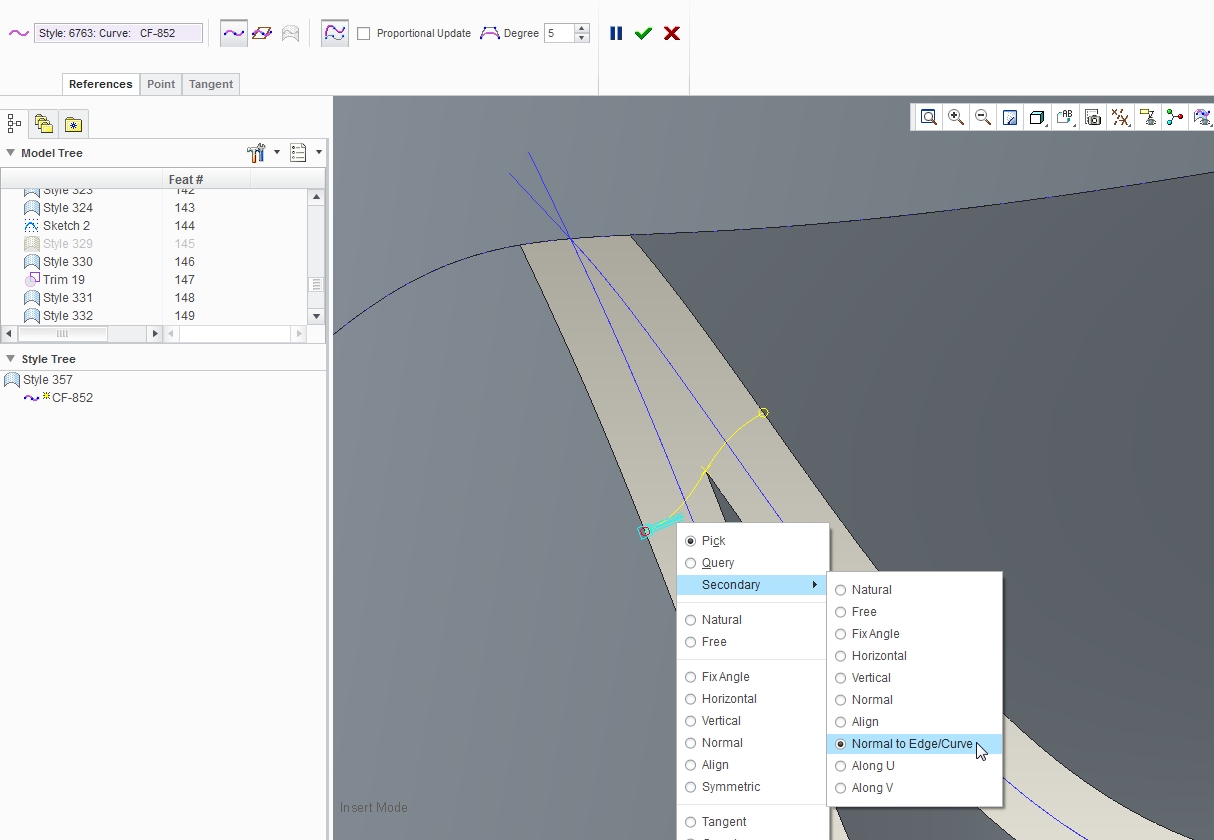

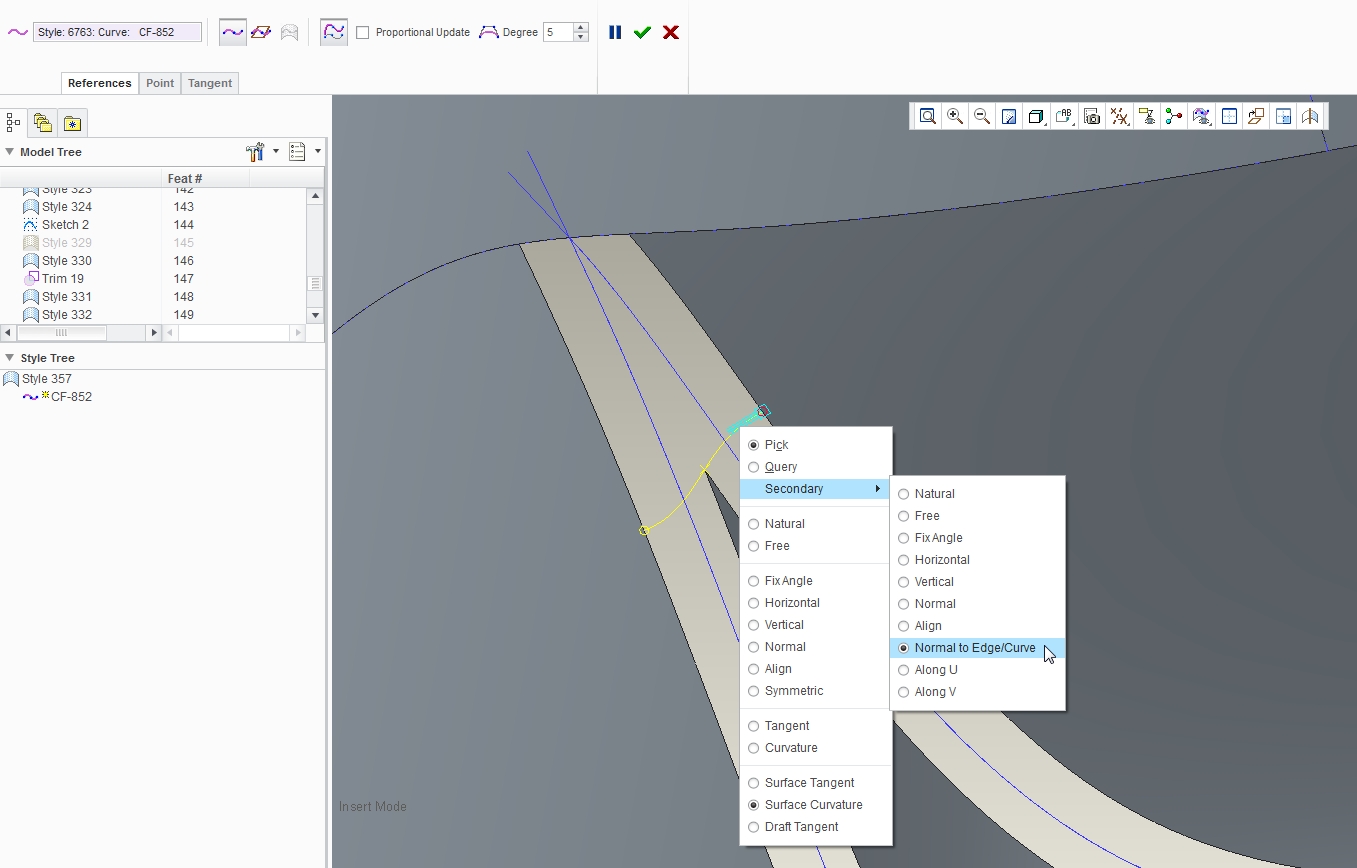

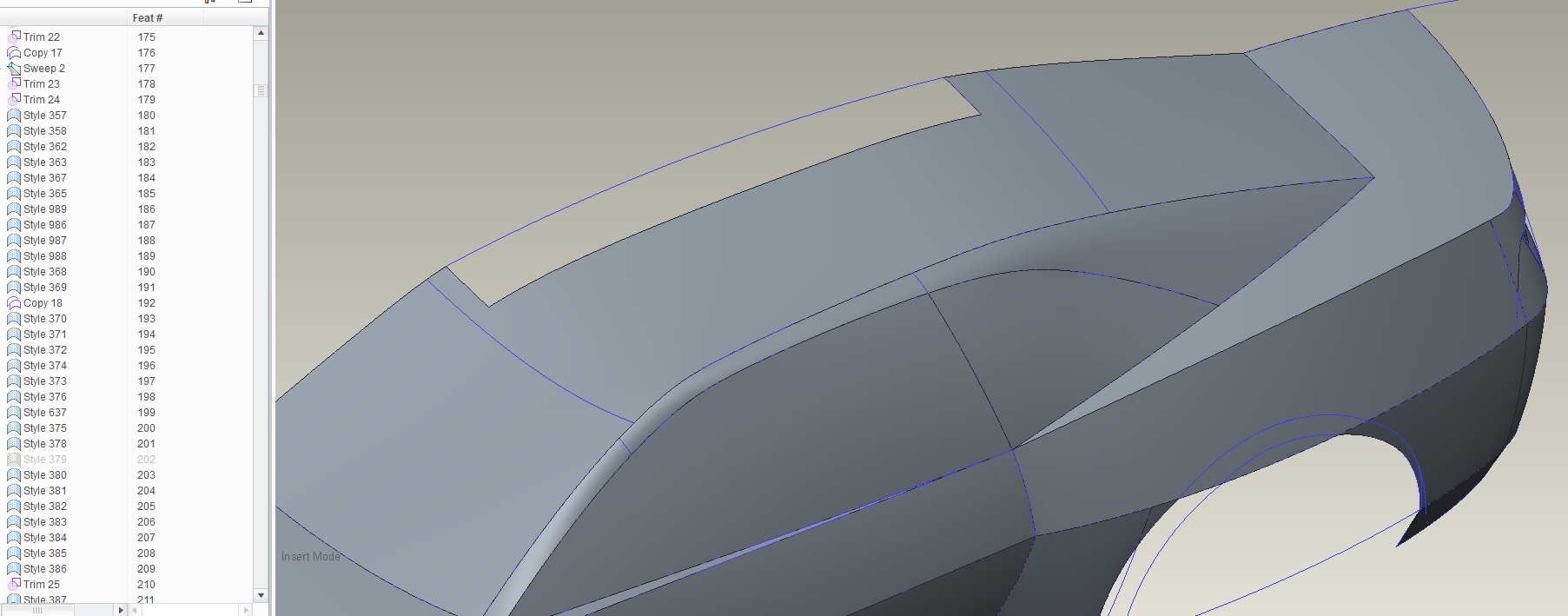

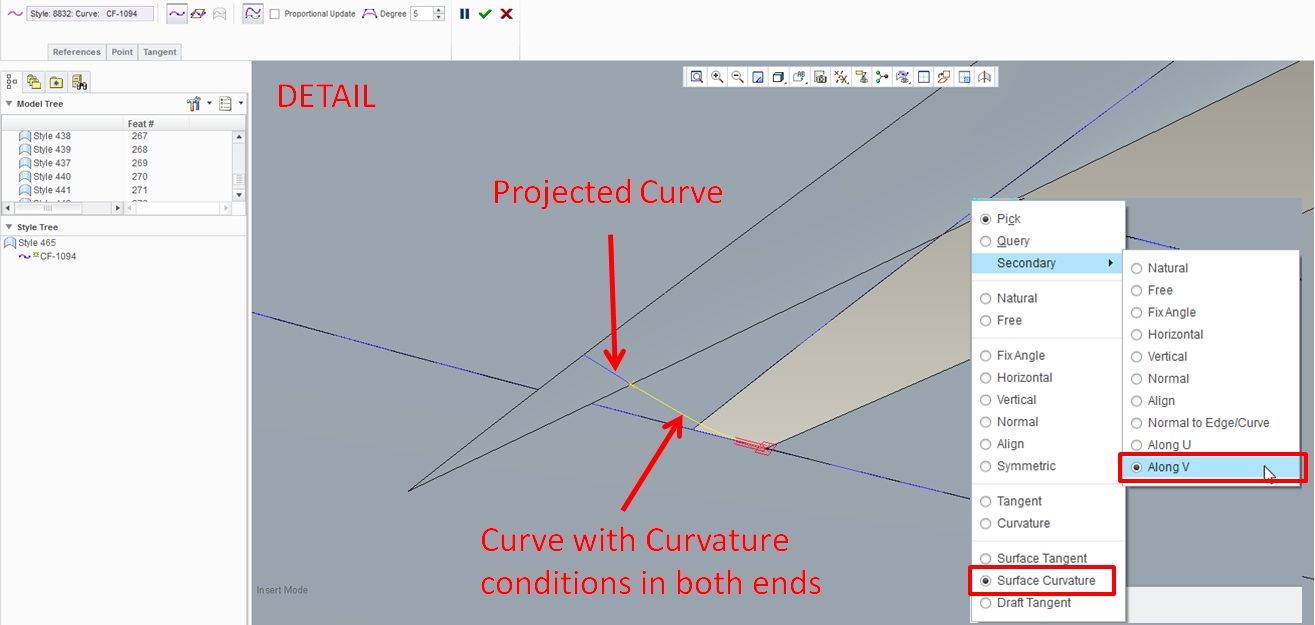

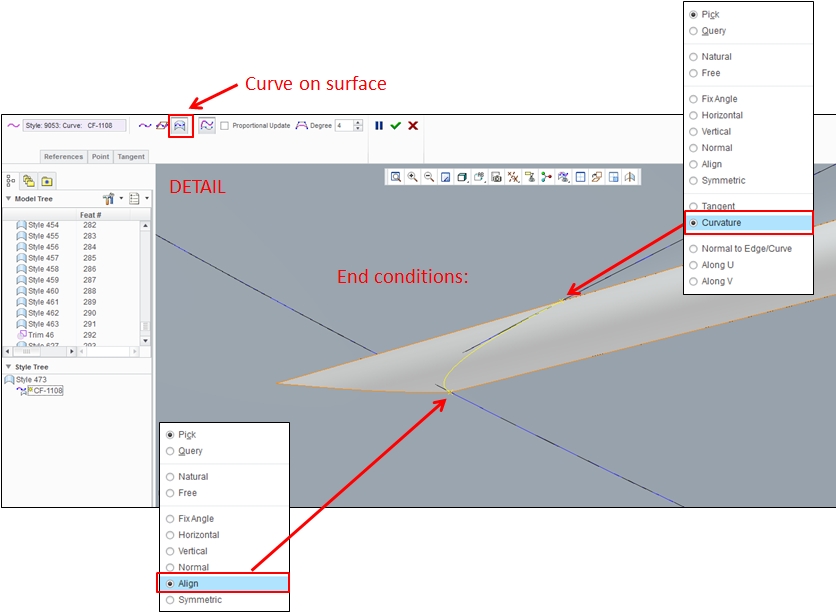

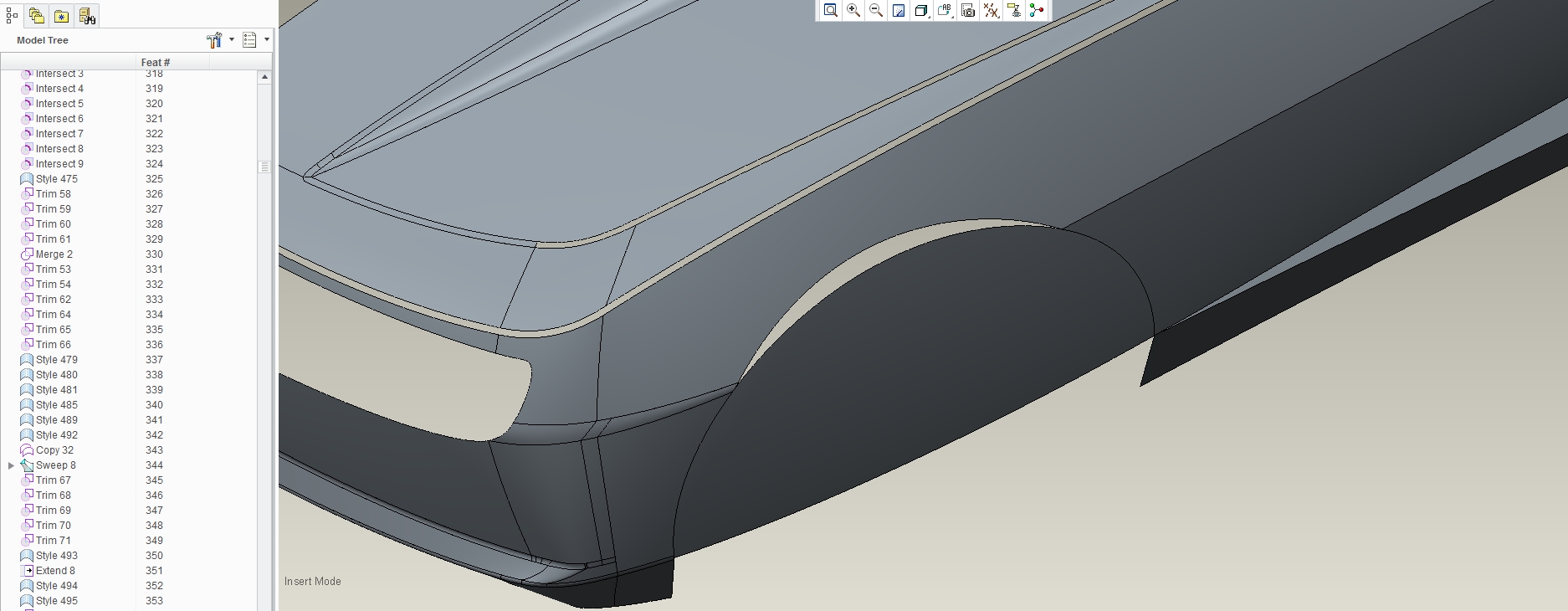

Hello Mark . I'm using styles surfaces because I think it is easier to create and I have better control of curvatures. I've been used to surfaces boundary blends since 1998... only last year I decided to learn this style metodology. I like to create spline curves in this mode instead creating in sketch mode, because in the old way I would have to create 2 projection curves... than intersect them to create a result that I would want.

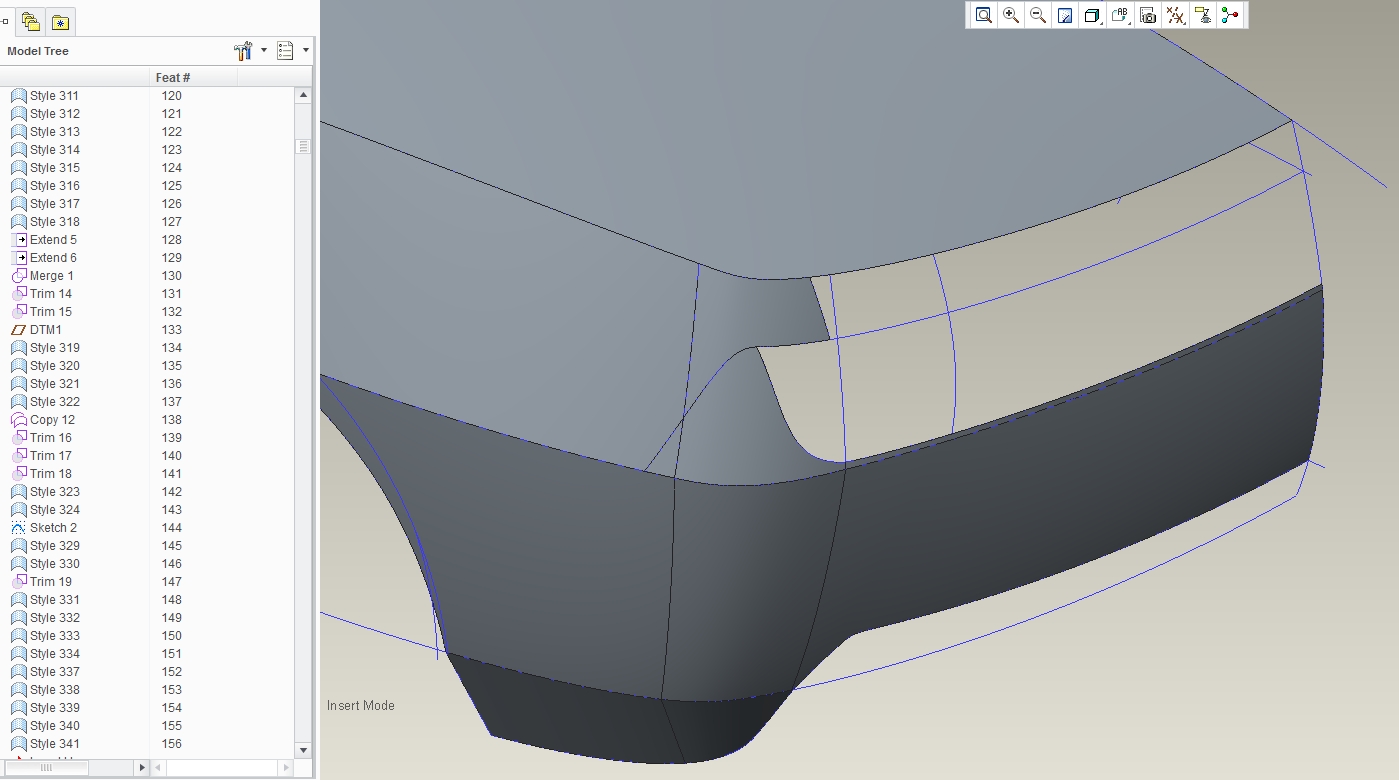

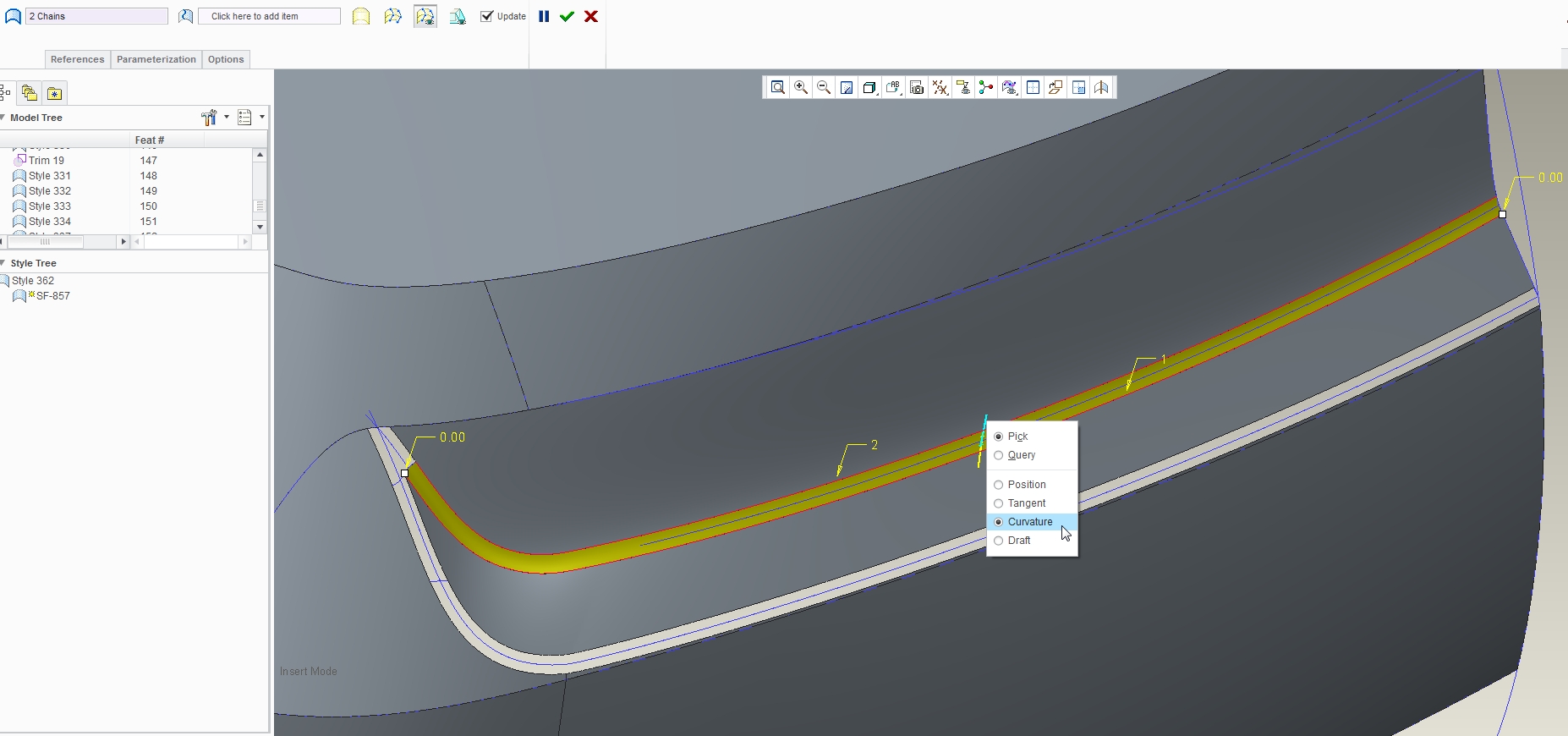

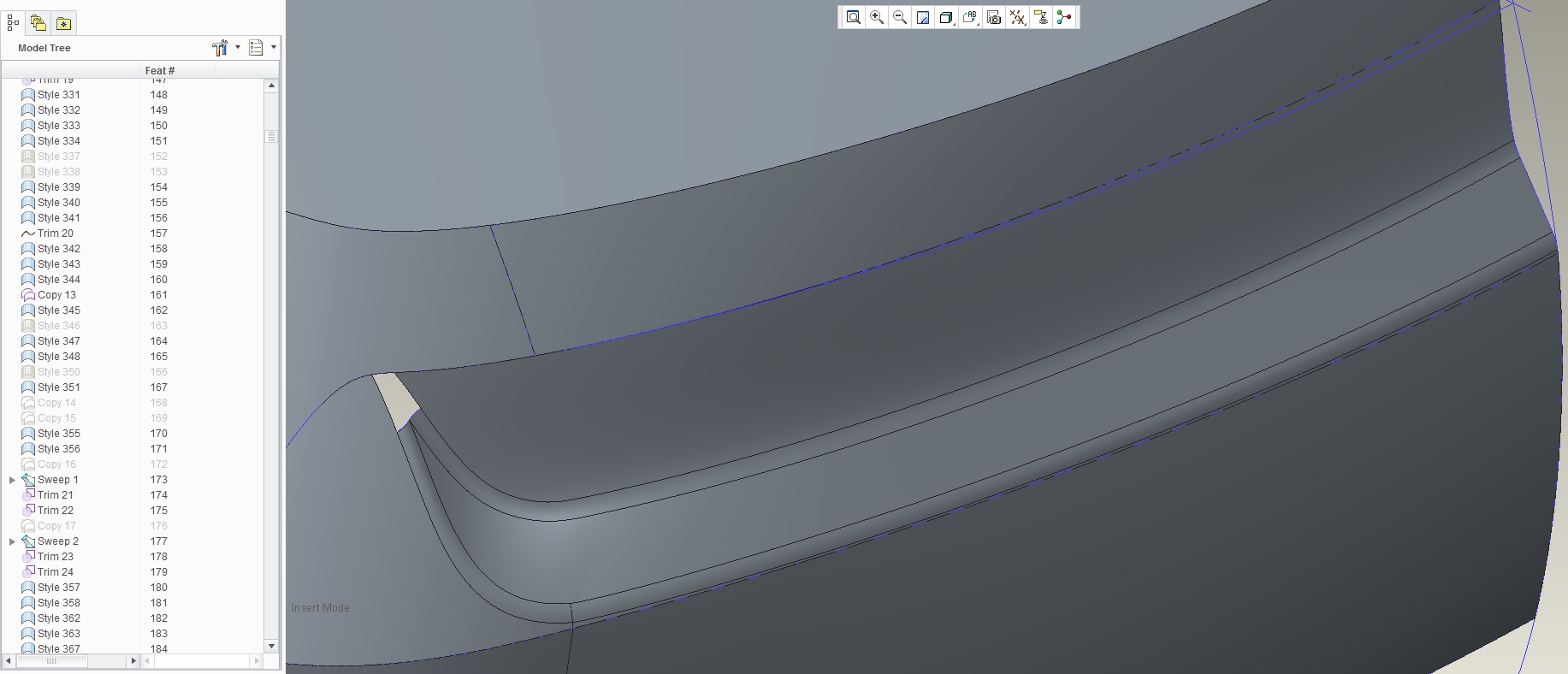

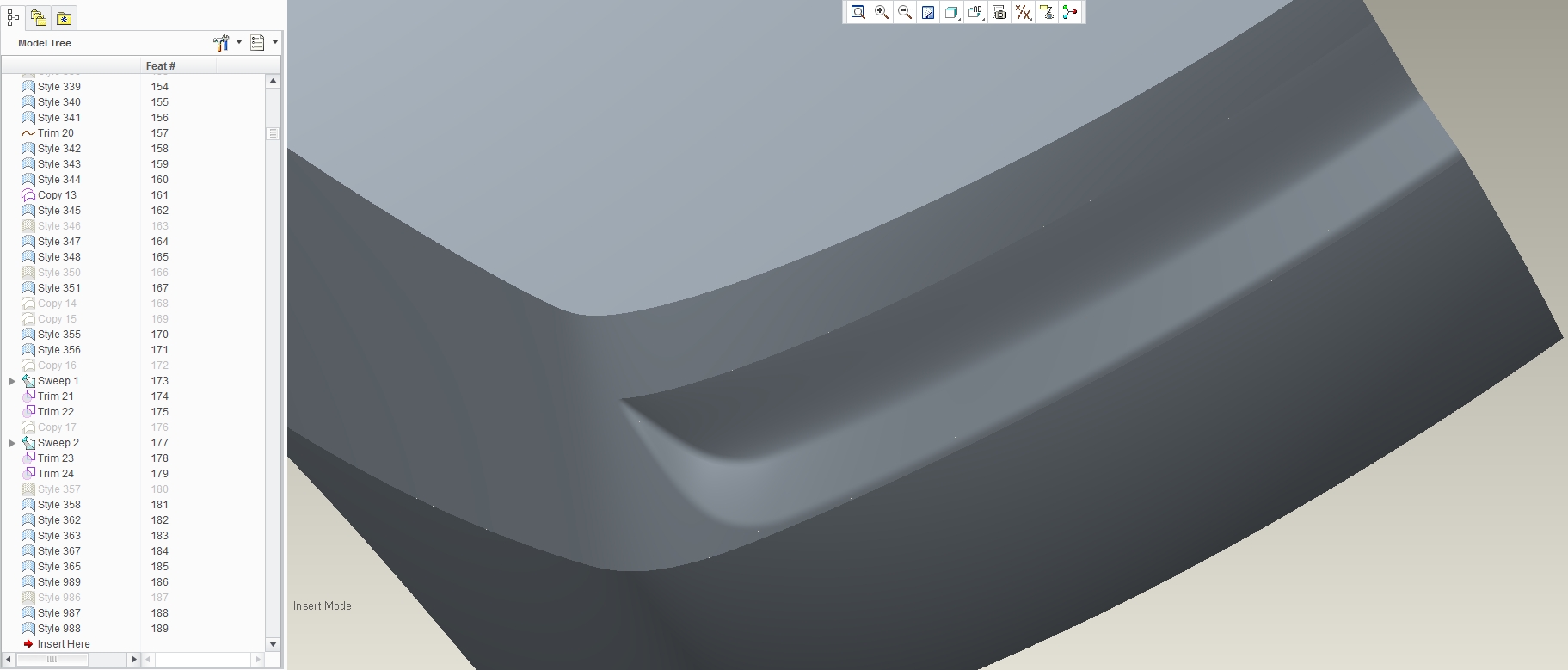

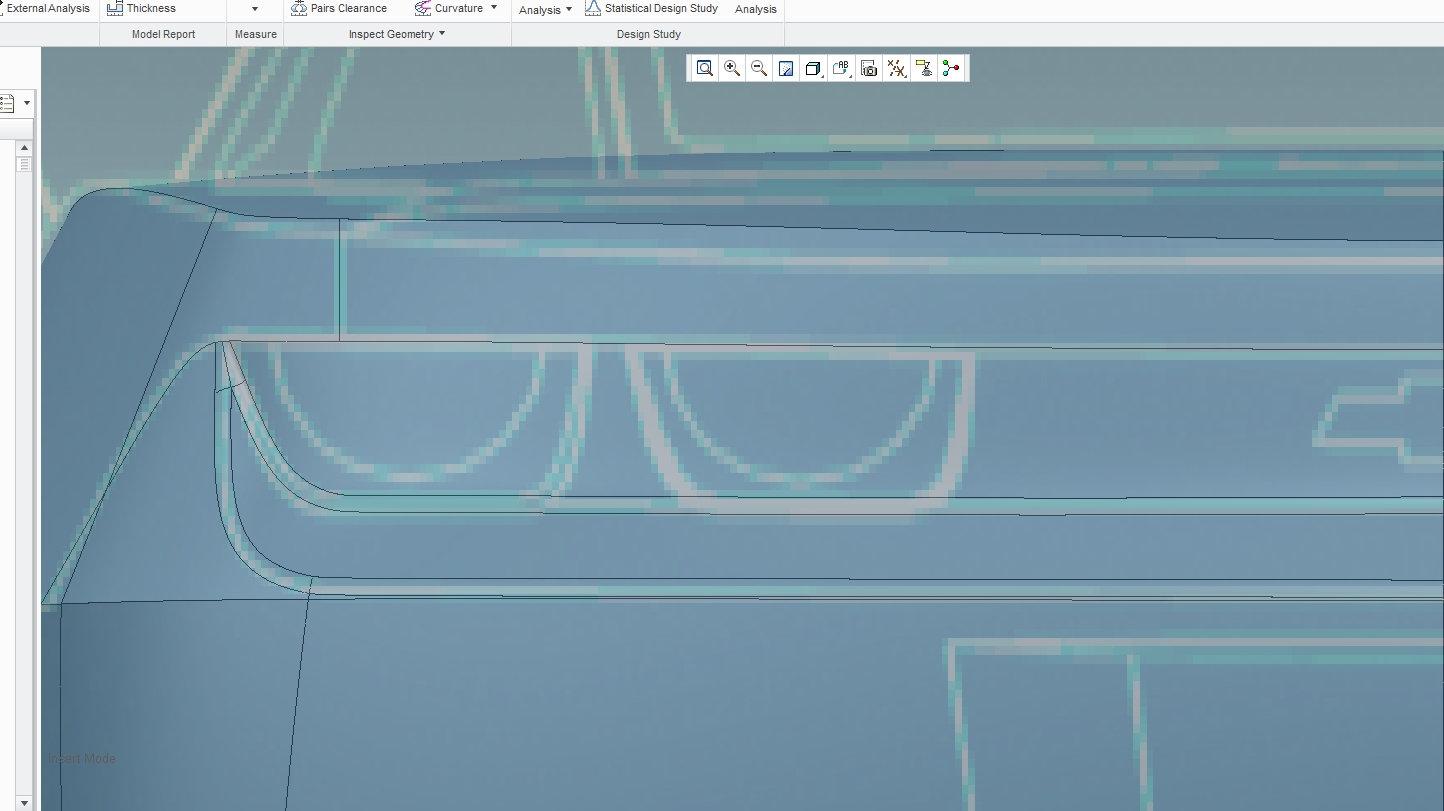

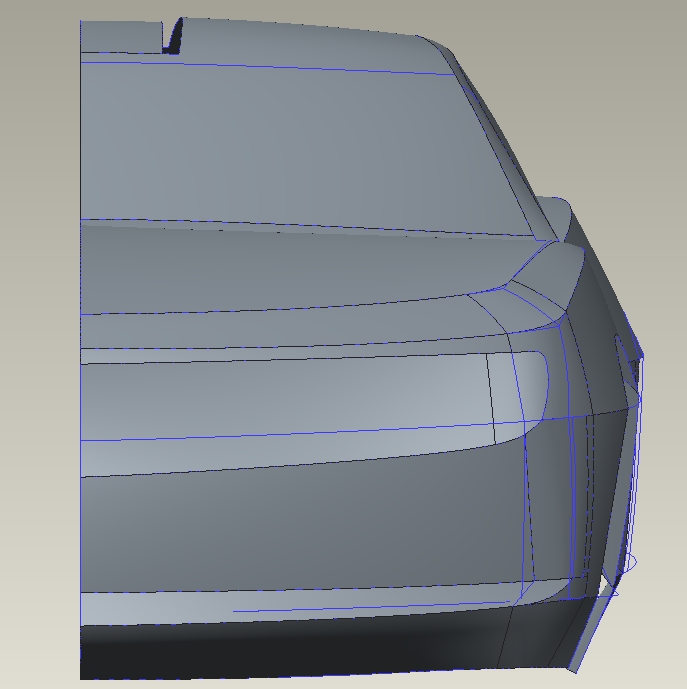

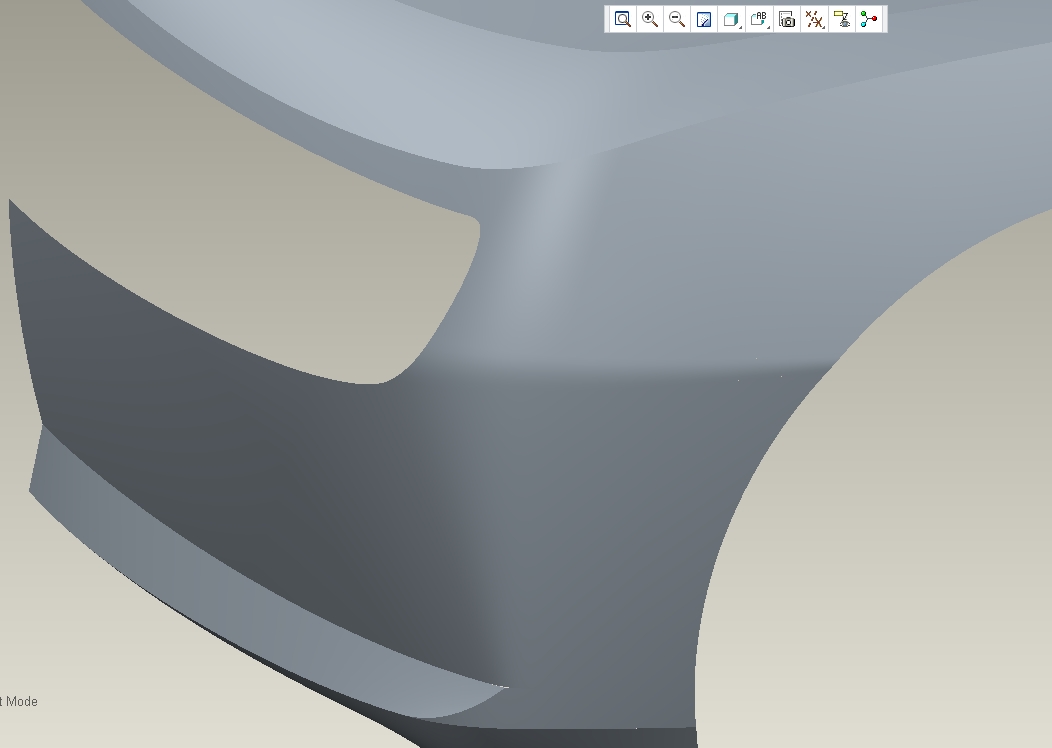

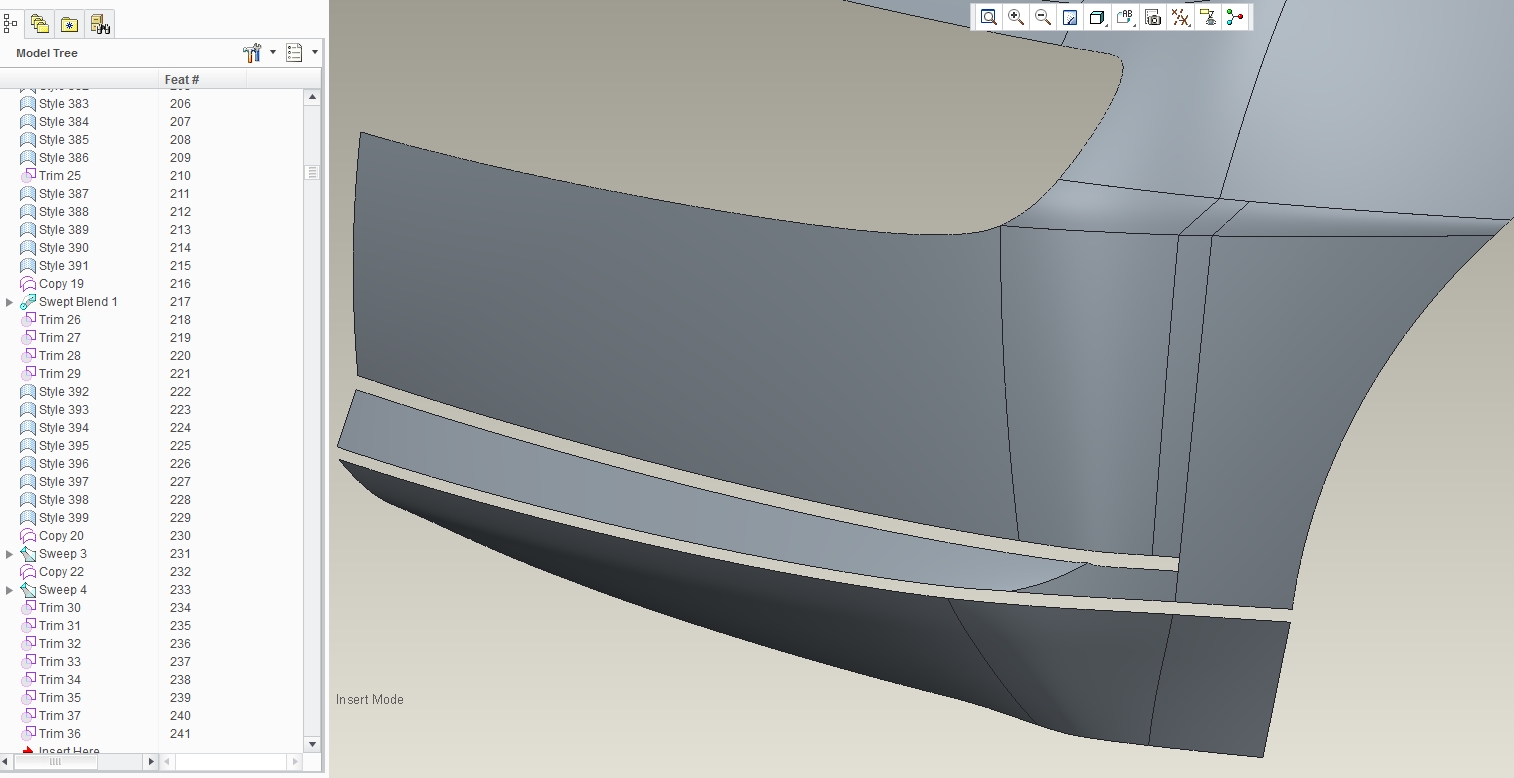

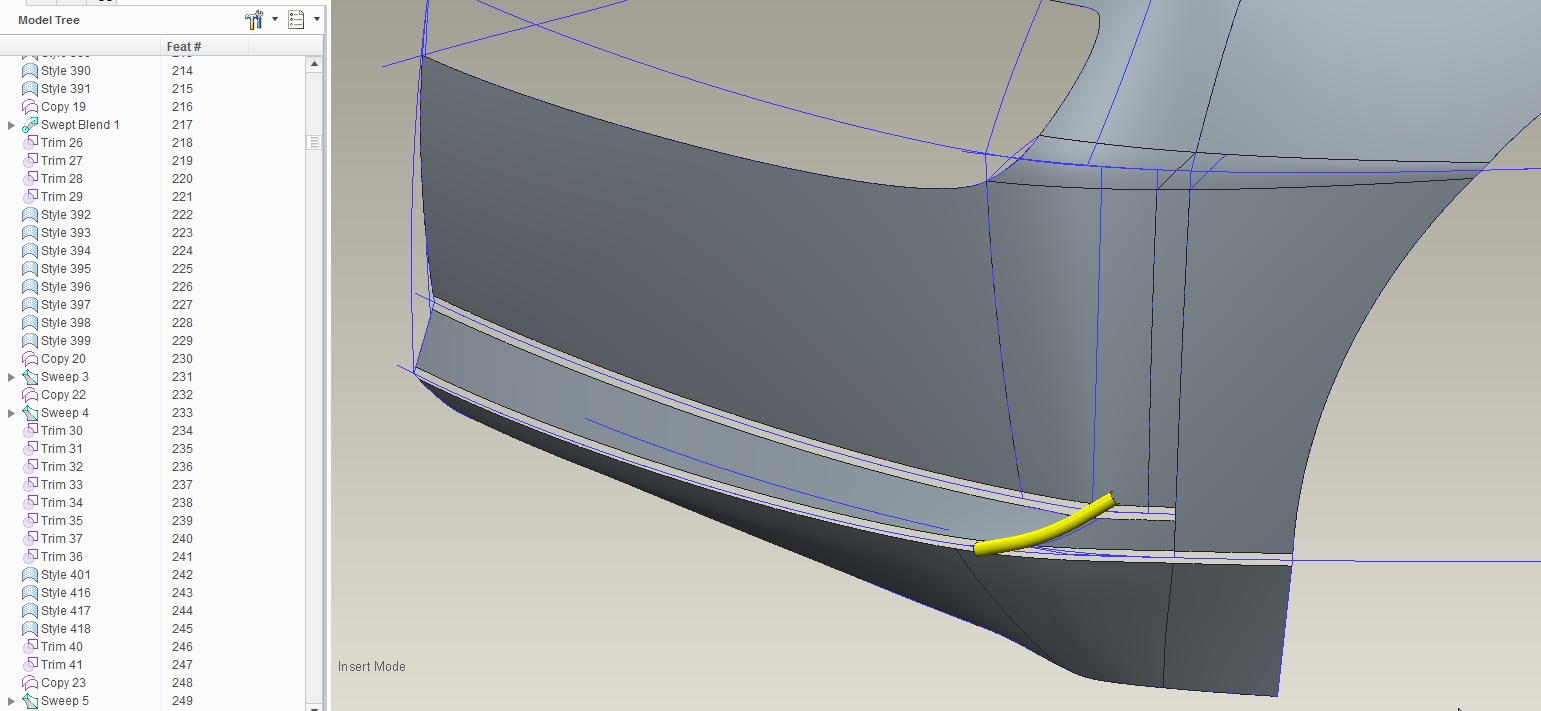

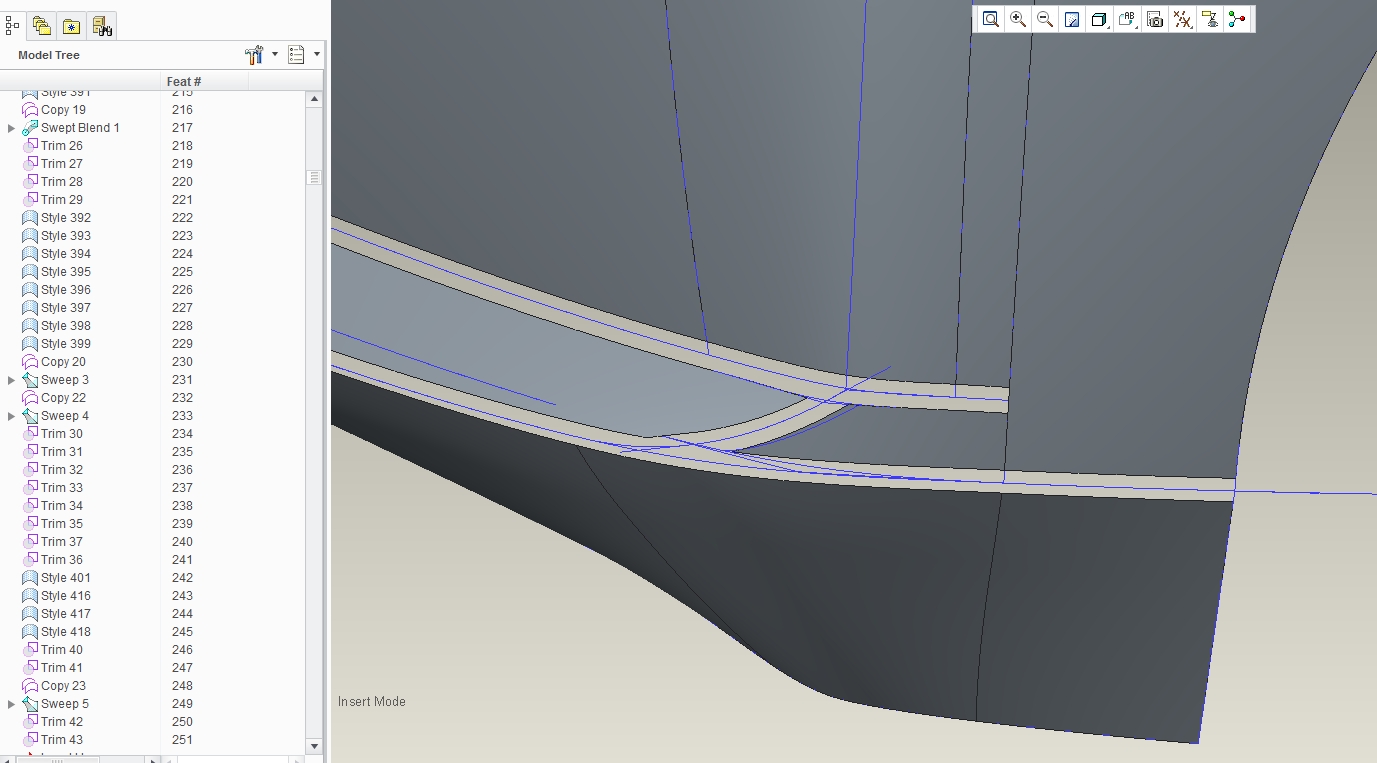

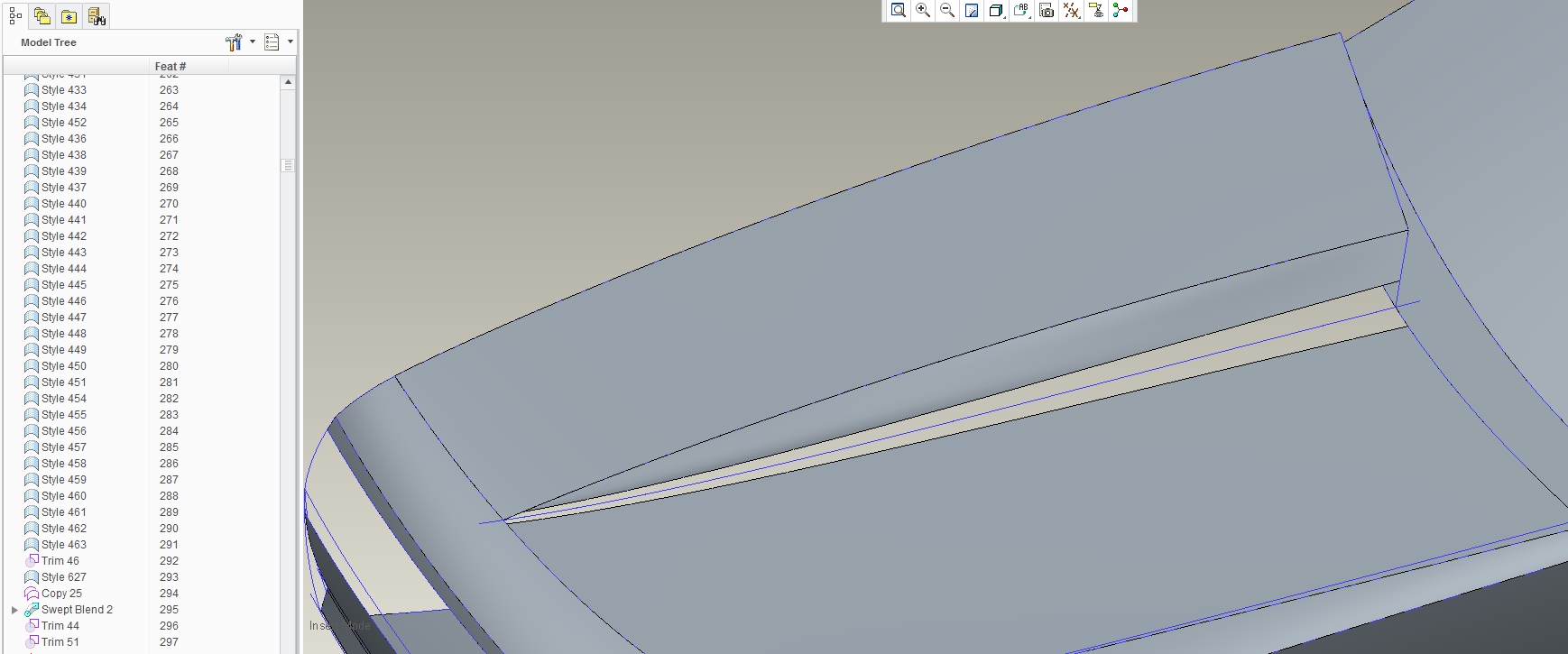

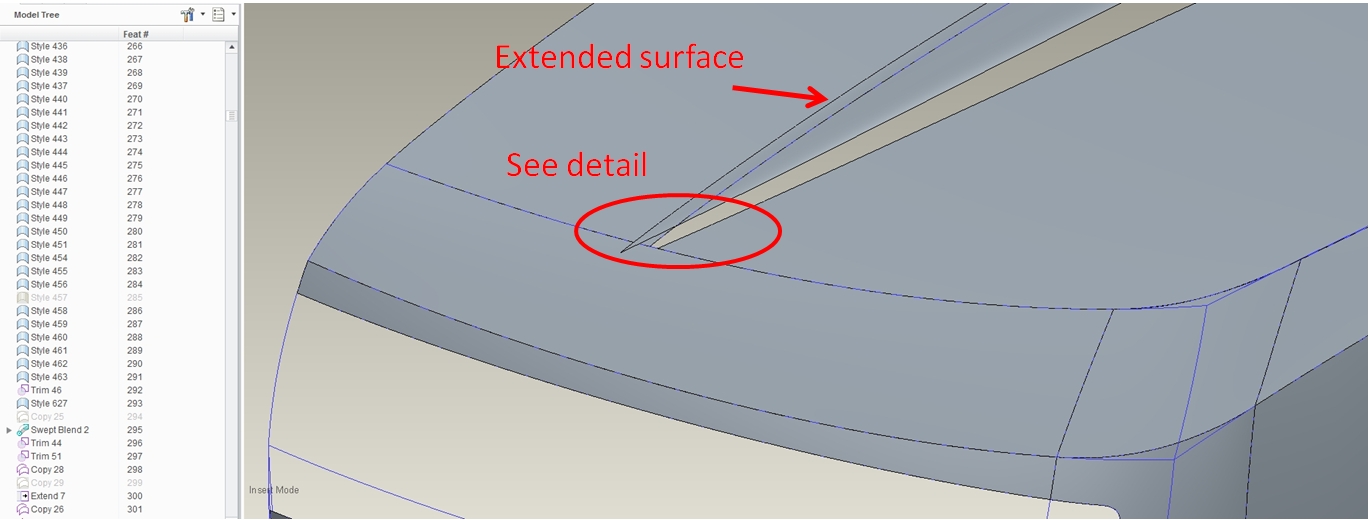

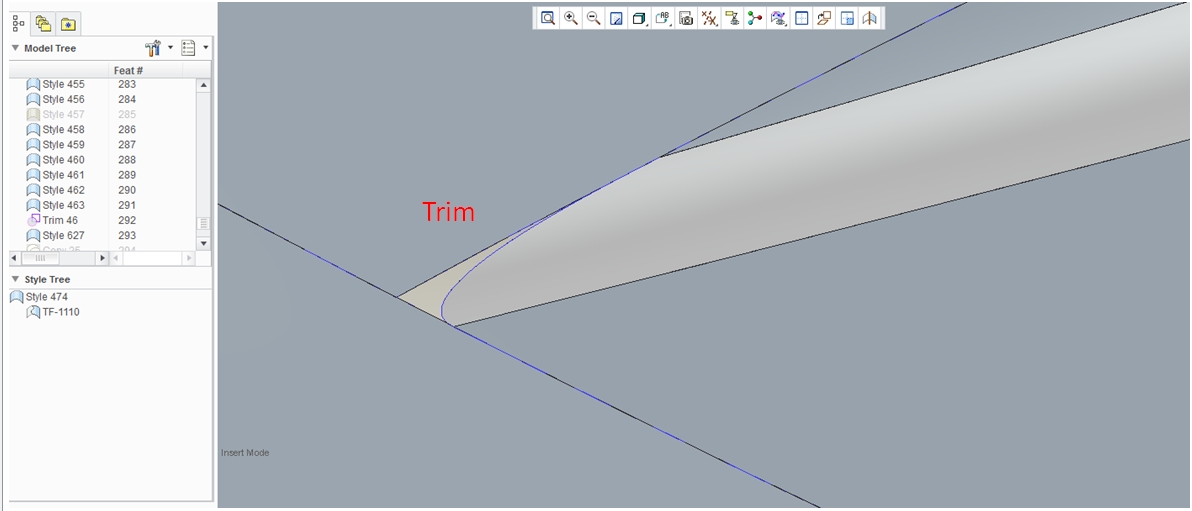

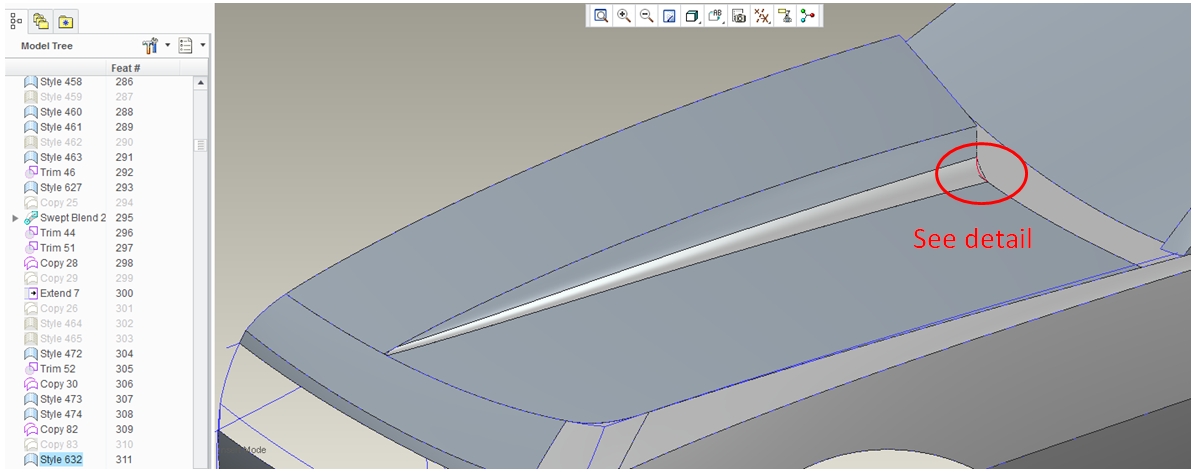

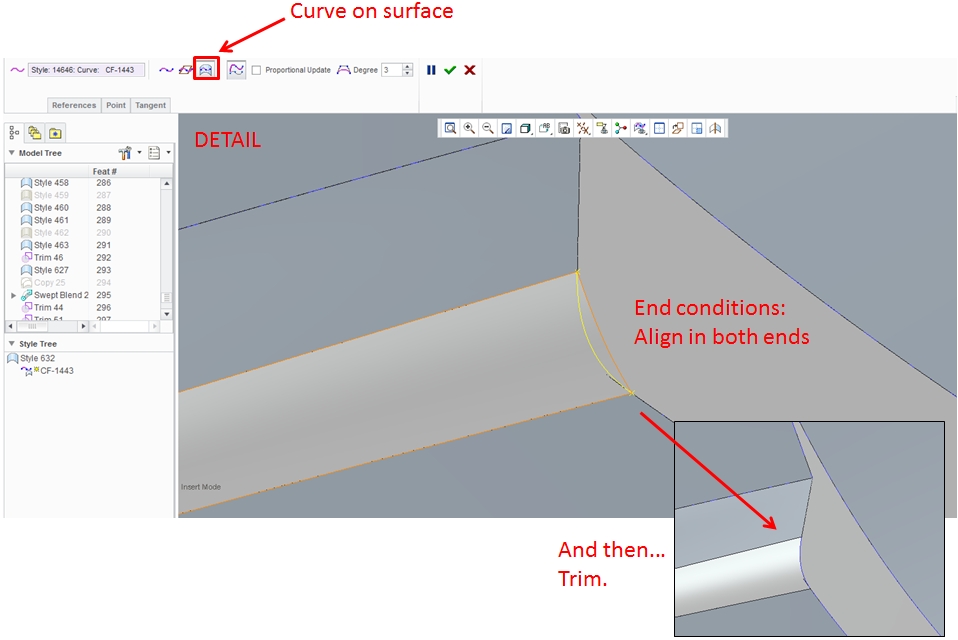

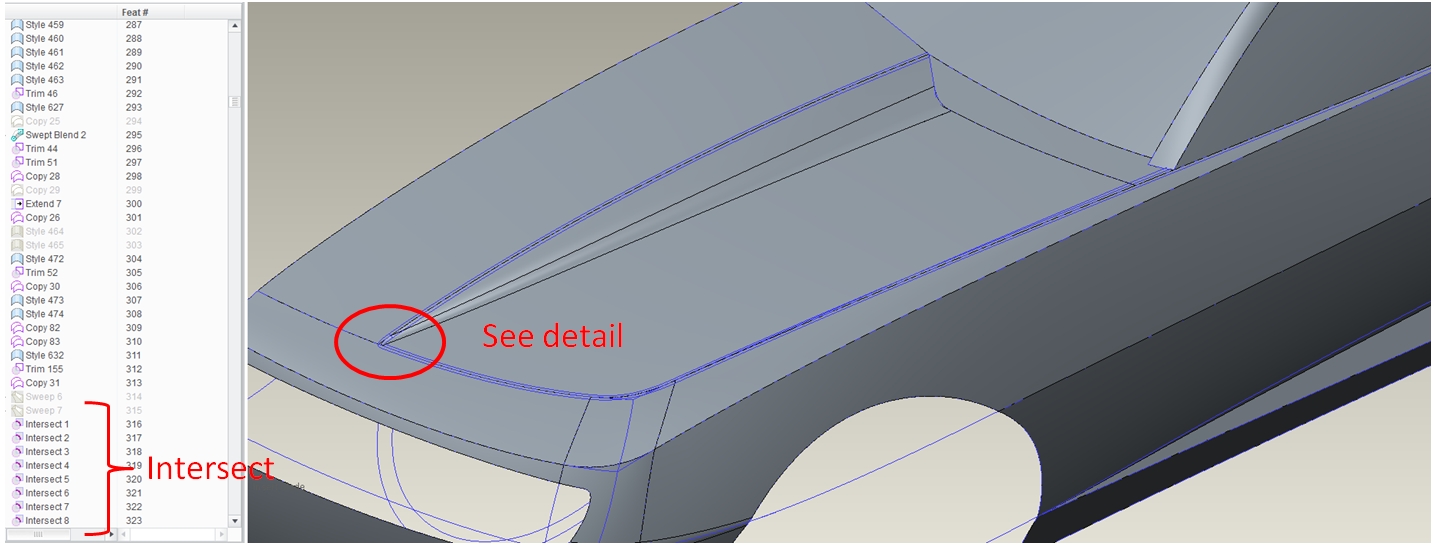

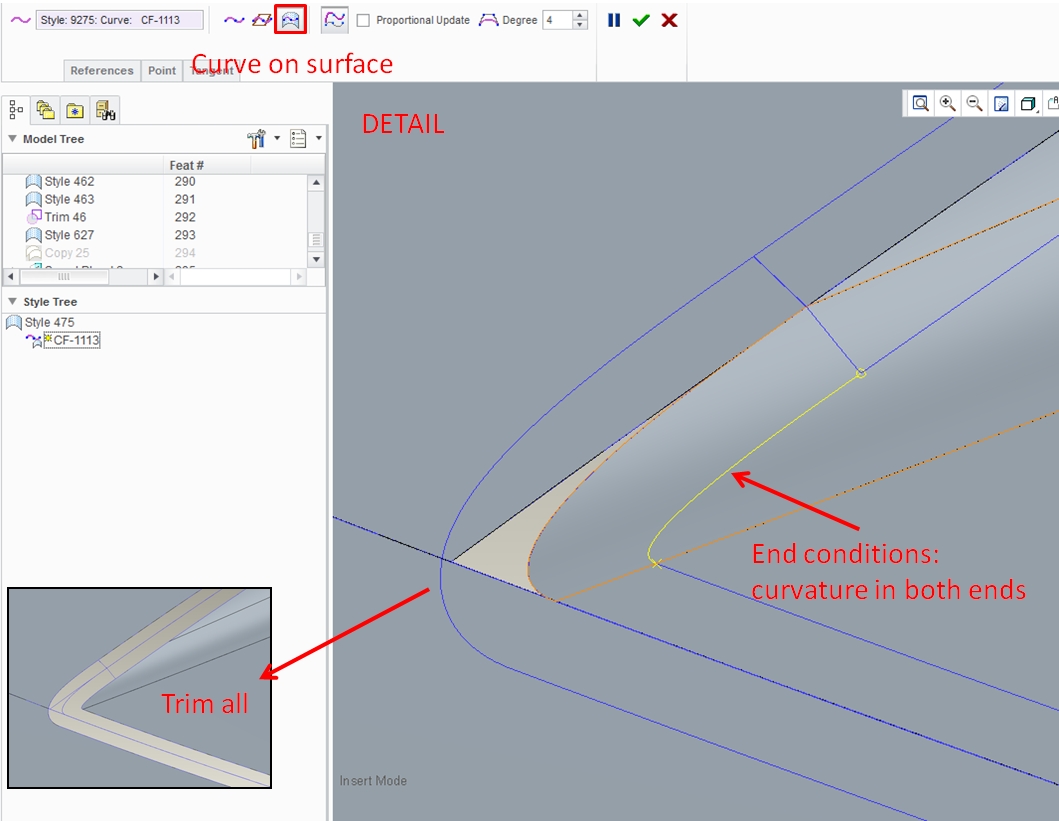

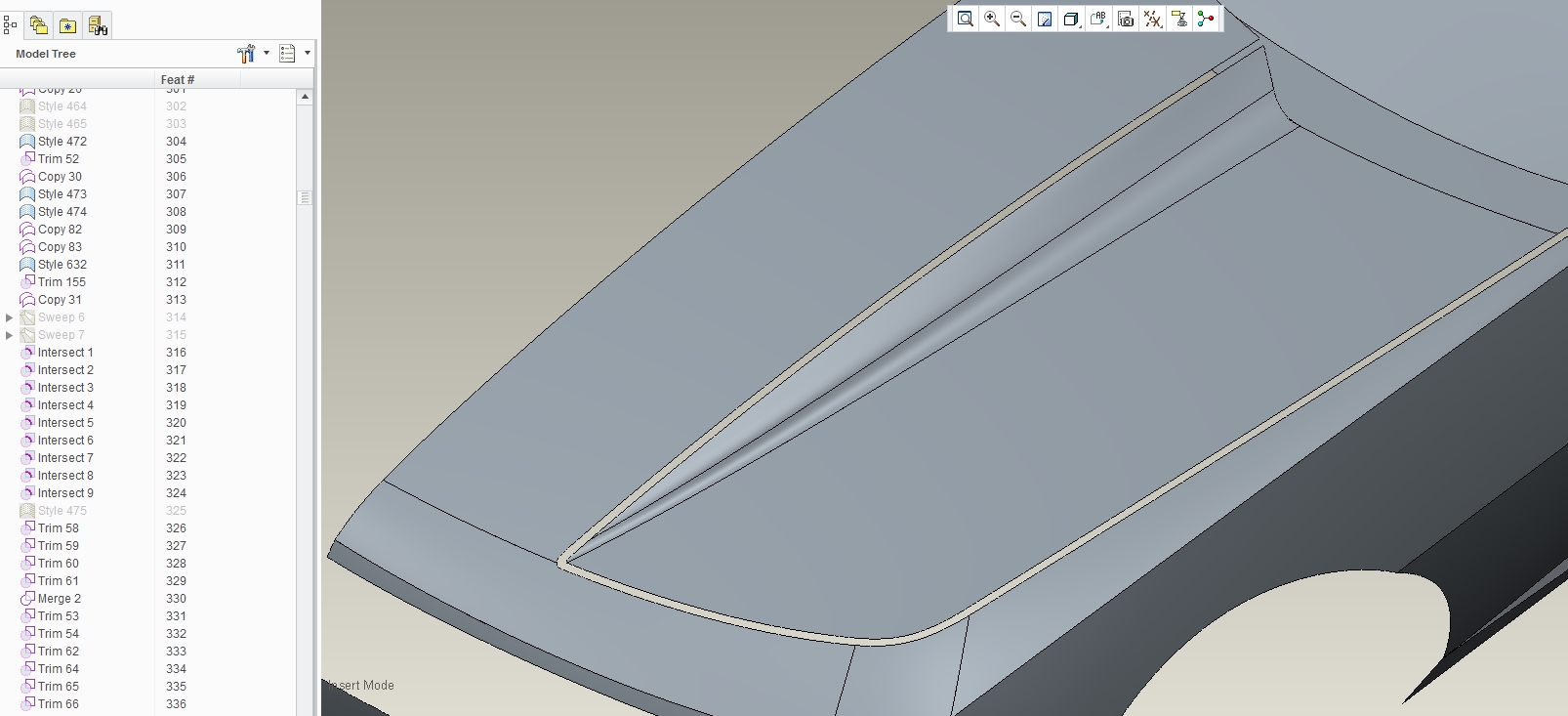

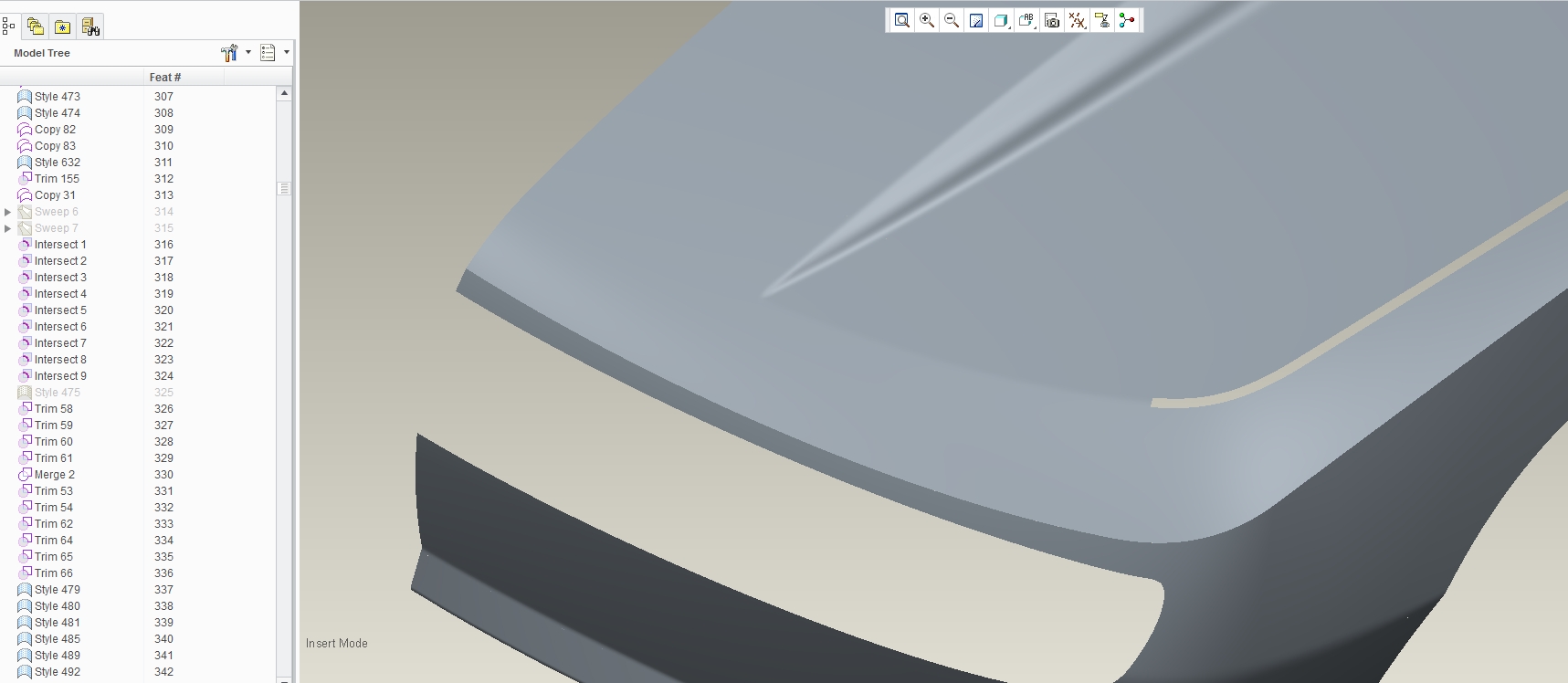

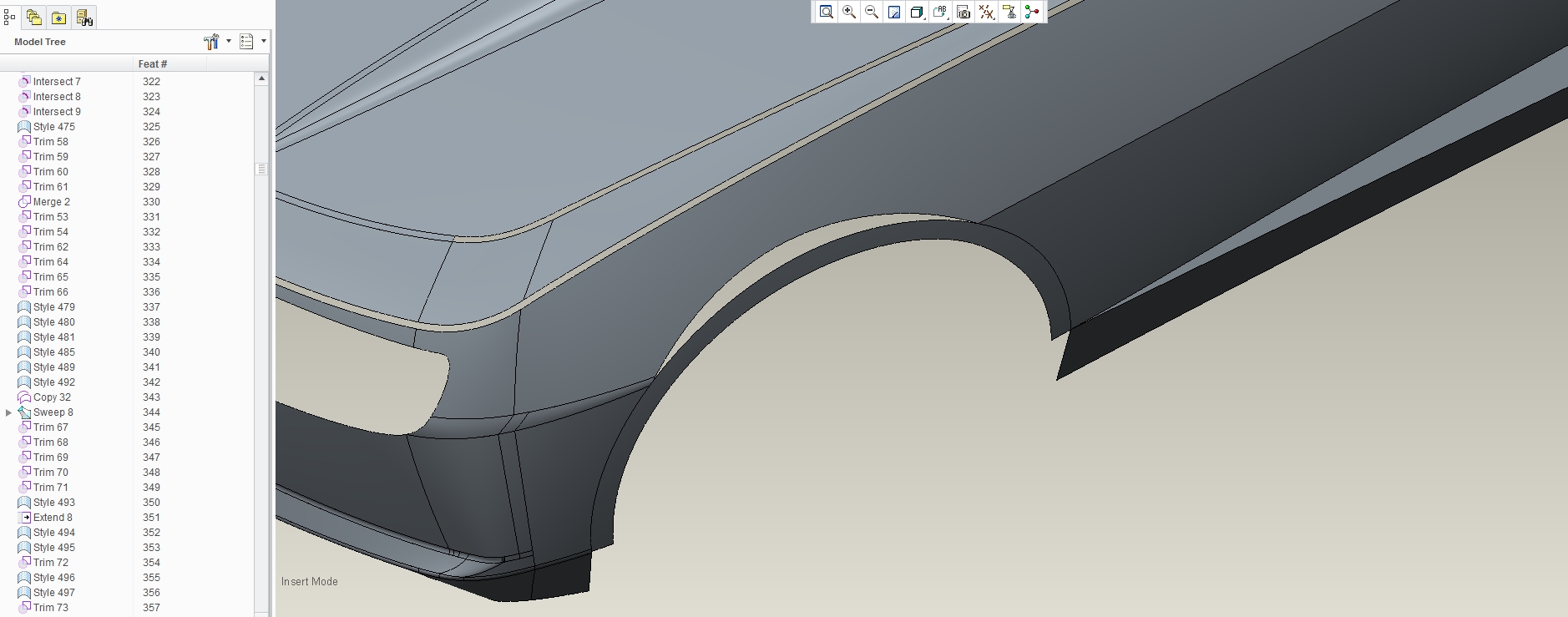

The yellow features, like you presumed, are sweep's that I made to trim the surfaces and control the chord of them, because the round feature doesn't work for me in this case, eventhough there is a new chordal round in Creo 3. They will deform because this it's called an "y fillet area" and I need to maintain the class A curvature quality.

You can ready more about Y fillets in Class A Surfaces here:

http://www.carbodydesign.com/archive/2010/06/y-fillet-class-a-surfaces-tutorial/

I don't see problems to work with style in Top Down Design since this style features are made with dimensional control of datum points and datum planes, even sketched control curves...

Thanks from Brazil.

Hug!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks for elaborating on the use of style surfaces, etc. I would like to learn them some day, but for my current needs I don't need anything near that precise regarding complex geometry. Looking forward to more updates. Wish I had the time to work on something like this. Enjoy!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Mark,

The short answer is Style is the closest thing to "Class A" Pro/E...e'hem, sorry Creo, can get.

The long answer is Creo cannot do traditional, verifiable Class A automotive surfacing. Hey, wait that was kind of a short answer too.

However, Marcio is using some Automotive Class A techniques in his surface work.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I just re-read my post and I realized I gave a potentially misleading statement. I stated that the Style feature was the closest thing that Creo can get to "Class A", which is true. I went on to state the "Creo" was not able to do traditional, verifiable Automotive Class A surfaces...when I actually meant to say that "Style" cannot do traditional, verifiable Automotive Class A surfaces. I made is sound like we have that ability in our software when we do not.

Apologies for getting you guys all fired up!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Has there been considerable improvement in ISDX module of PTC Creo Parametric?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Rohit,

I wouldn't say 'considerable' because Style (ISDX) is still the same animal at it core. There have been some what I call 'goodies' added over the last 10 years to make it easier to use and give more control and feedback. Some neat curve controls were added back around WF5 timeframe. The model tree got a little better. Style and regular features play together better now than they did some time ago. I think rendering has gotten better, but that is suite wide too. I still want a "Turn Table" real rendering tool. IE. animated the object around an axis or on a plane while in perspective. This is more a tool in Animation function but it should be in Style as a 'one click' deal.

Actually, I think Freeform has been given a little bit more attention than Style. Up to Creo 2 Freeform was included. I am not sure if it is in 3 or 4. I am sure someone out there knows. But Freeform (Sub-D) modeling looks really interesting. Given time it might be pretty cool.

That is my $.02

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

PTC Creo - What Every Engineer Should Know About Ugly Product Design

so can Creo do class A surfacing or not?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I thought we answered this question.

Technically, Creo can create "Class A" surfaces. Realistically...it's not even close in ease of functionality to do it with Creo for all the reasons (and more) discussed within Marcio's thread. Remember, there is a huge difference between "Class A" surfacing and creating "smooth" surfaces in a model.

I am curious, what type of products do you model?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I was just curious.We are into injection molding and casting of polyurethane.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Industrial design capabilities do not equal true automotive class A surfacing capabilities.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

We are getting close to legitimate A-Class surfacing like at GM tho with Creo. With our ability to in Style to utilize y=x^5 and greater curves plus we can see Knots. This compares closely to how and what we teach in our Alias AutoStudio class. We got one of the product line managers from 15+ years ago to take an Alias class. I presented in 2008 to the Creo World conference and presented Alias studio the entire time LOL

Bart Brejcaha

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Bart,

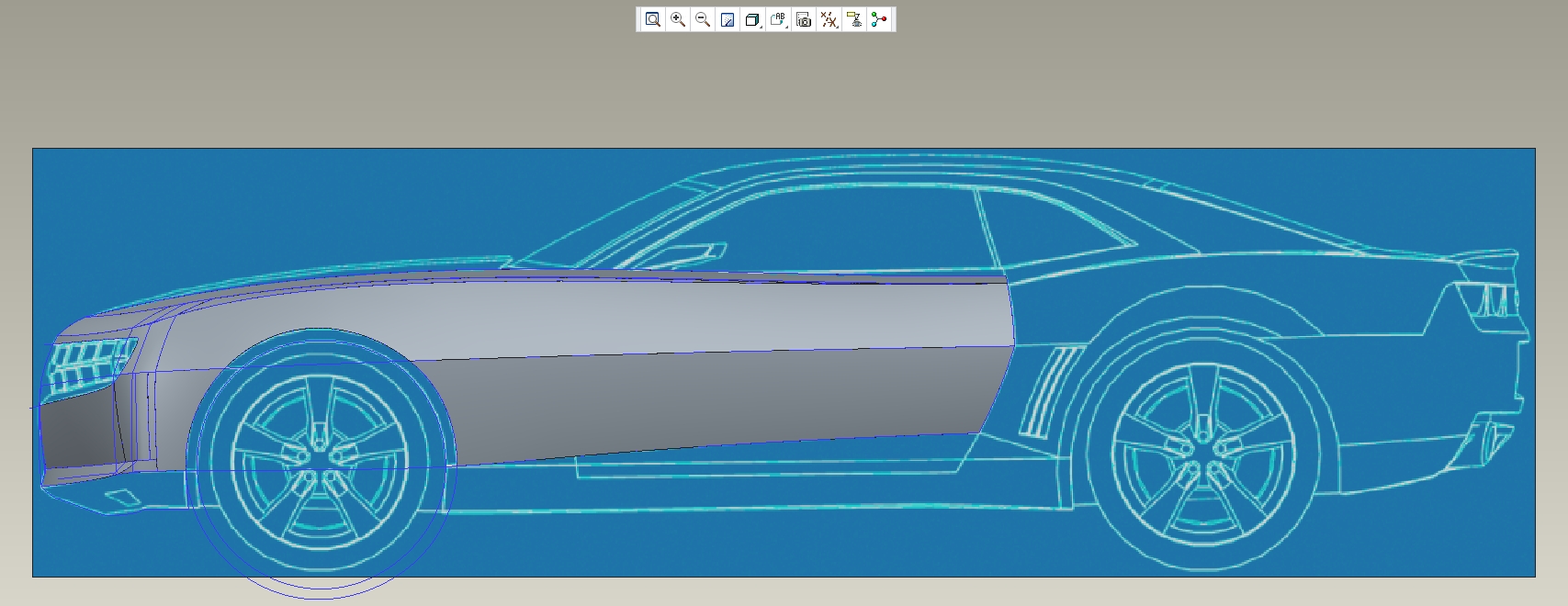

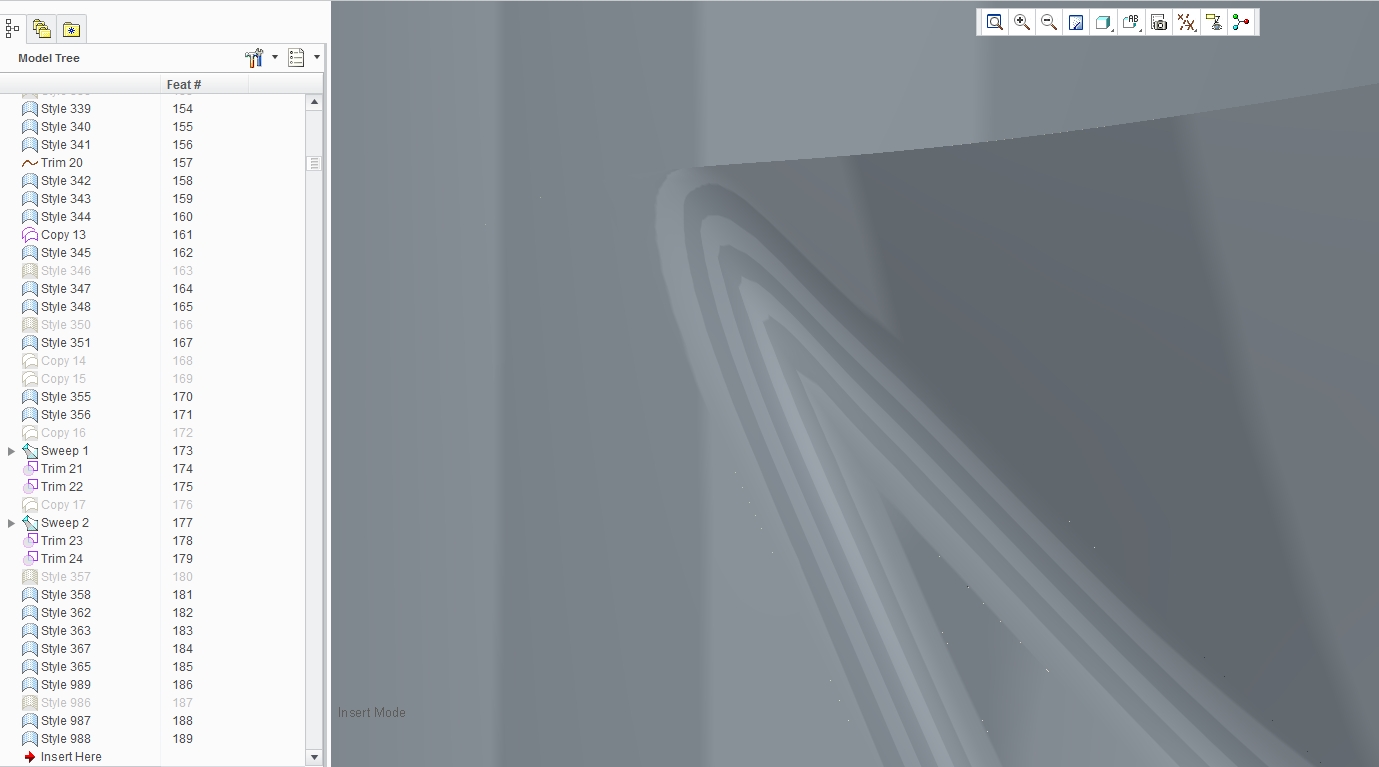

I know we have been around longer than dirt with the PTC suite. The Disclaimer: I have not seen 4 yet nor know all the "Skunk-Works" stuff that I assume is happening with the developers. But I have to ask what you mean by "We are getting close to legitimate A-Class surfacing like at GM tho with Creo"? If you mean G2 smooth surfaces on some swoopy-doopy part....well ok. But, I have to also ask if you have ever designed BIW (Body In White) for a shiny, gloss painted, highly reflective, out in the bright sunlight vehicles? I wonder because, at least up through Creo 2, there is no way, for any amount of money I would ever sign up to create from scanned clay and release for stamping the Camaro body panels that Marcio has made. While very impressive and cool to watch his work progress and skills getting better with the Style feature...what Marcio is creating are essentially Boundary Blends with G2. That is not technically "Class A surfacing".

I mean no flame on...but unless Creo Style Feature 4/5/6 has been dramatically revamped to include simple things listed below...Creo as a true "Class A" tool is still waaaaaaaay off in Ether-Land.

Ultra crisp reflection curves

A virtual turntable for viewing reflection curves

Boundary matching to G3 WITH surface interpolation and the ability to keep water tight volume

Surface/Node/Knot manipulation that does not result in independent floating surfaces not part of the original.

How about just simple robust Node/Knot manipulation?

More intuitive Parent/Child indicators

Curve trimming/combining with the ability to smooth/parse.

Modeling in perspective

SOME structure to the model tree.

Much More....

Can we still be friends? ![]()

Thought I would add something that occurred to me this morning as I FOUGHT a G2 radius for hours with Style. How about a G2 round tool actually IN the Superfeature???? That is Class-A 101 functionality. Having to actually build the rad in Style is a PITA. And while I am at it....all this is really pointless as an argument as Style (ISDX) is a still a curve based tool...not a surface based tool. No amount of window dressing will make this a Class A tool, in my opinion. I just hope I am not retired before it actually has all the bells and whistles we need for real design! ![]()

PTC, you should have kept ICEM/Surf in the stable long ago. Selling it was a huge mistake.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Marcio,

Your surface work is coming along very nicely and your Camaro is looking pretty good. But I want to clarify that describing the surface work you are doing as "Class A Automotive is not really correct. You are essentially creating boundary surfaces using the Style feature that has G2 continuity in most places. There is a huge difference in what you are creating to actual automotive quality Class A. I am not trying to negate what you are doing. I am simply making sure users know the difference.

All the best.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you Dean Long. I apologize for my mistake.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

No apologies necessary. You are doing some great work there. Style is pretty cool and having that experience is invaluable.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Is there a short explanation of how class A surfaces are created or need to be created? Just curious as I don't have a current need, but always interested in learning better modeling techniques.