Community Tip - You can change your system assigned username to something more personal in your community settings. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Quick question re. surface regions

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Quick question re. surface regions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Quick question re. surface regions

Am I (and my colleague) right in thinking that surface (and volume) regions are part-level features, and therefore cannot be created on surfaces resulting from an assembly-level cut?

If so I may submit an Idea...

Thanks!

- Labels:

-

Assembly Design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I think (not 100% sure) you are correct. I usually stay away from assembly cuts in models that I use for simulation. A workaround: if you want utilize symmetry in an assembly, make an assembly cut, export a step, open the step file and work on that for simulation. You loose parametric control, but also remove all dependencies which is useful when you adapt your model for simulation. Fortunately there are modeling tools, feature recognition tool etc. that are useful when working on imported step geometry. Some parametric control can be added to the model quite easily...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Jonathan

I just tried (creo 3.0 M060)

If you have an assembly with a cut in it, and you want to select a component to make a surface region on, I get an error message: "Component can not be modified. Select another component to continue"

Of Course Mats' trick is an option, I might choose to add a feature (small protrusion) if I need the region in an assembly that has been cut.

Please go ahead and submit the idea. I find it more of a nuisance when the surface region was present in an early generation of the model and causes all kind of errors and regeneration issues when you make an assembly cut at a later stage.

Erik

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Another contribution for this small topic,

The use of volumes (more than surfaces) has a "little" more complicate behavior in Creo than you would expect for such "easy" feature.

To complete Creo´s lousy help files don´t give you enough clue when things goes wrong or cannot be done.

I gave up trying to make the volumes in assembly exactly due to this "Component can not be modified..." message. Thus I have to make the volumes directly in the parts and even so the output is not always good. Here come some extra problems. Not all type of "volume regions" are tolerated in assembly with a "cut" or even "solidify".

I´m currently in a phase that requires to use a lot 3D contact with non-linear material (rubber). This is very slowly in Creo (2.0) and non-convergence is a common problem.

For this reason I need to use symmetry when possible and also to prepare the elements near the contact region (ex. mapped mesh).

The unique "volume region" that seems to work well is simple "extrude" and even so only with a simple made geometry. If you use "project" or "offset" to create your extrude region the volume will not be correct in the assembly with a cut or solidify. In the same way "Revolve" may be simply ignored if you use projected features to construct the region. I have not tried the other volume features.

To make things more difficult I have the feeling that there are some models (assembly) that goes better than others - but it is difficult to get a pattern here. It looks like that some operations can have a kind of cross-talk. For example I feel that I have more problems to create volumes if another feature is present before (ex. contacts). As it seems the volume will not disappear in the assembly if you can input the FEM features in the right sequence - including cut or solidify.

I agree that the surface/volume regions should be more robust and work without restrictions in assembly with cuts.

R. Rabe

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Jonathan,

Yes, surface and volume regions are part level geometry features.

The behaviour with surface regions and assy cuts has varied with release.

A long time ago (version 18 ish?) the work around to create a surface region on a component that then sees an assy cut was to open the part and create the region in part mode. The region (or partial region) was then available in assy mode. I am sure I got this gem of wisdom when I was at PTC, a methodology document written by a Mechanica Consultant other than myself.

Anyway, this was ok until about WF4 M150 when I noticed the behaviour changed.

I did what I always do and the surface region was suppressed when returning to assy mode.

Then another release it was back to the good ol' days.

Then not.

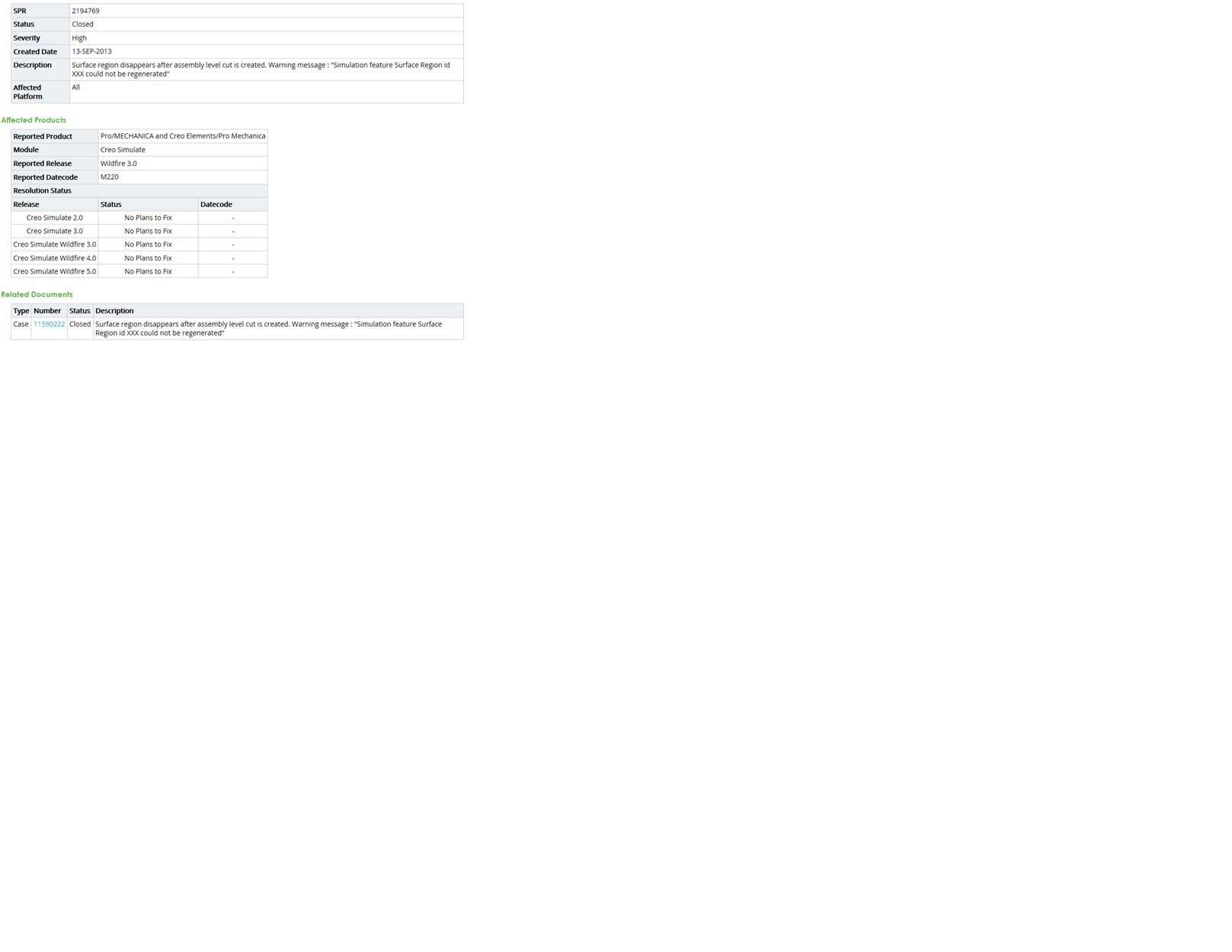

I commented here and raised a call that was initially closed as 'working to spec'. The call then became confounded with how failed simulation features are handled; not the original reason for the call.

The fact that it used to work didn't seem to be investigated.

I now have to go through the painful exercise of cutting parts up

Perhaps the work around worked due to a bug?

I liked that bug. Give it back.

bfn

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

... It seems that in Creo3.0 m110, the old fashioned method works again.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Dear Jonathan,

you have two ways to cut surfaces or volumes from parts affected by assembly-level extrusions:

- In Creo (not in Simulate) select the assembly-level extrude (necessarily a cut) and use the command "Model Intent" Designate. With it you can force the assembly-level extrude to be "copied" inside the single parts. You can also chose if to synchronize it or not between assembly and parts. Once the extrude is in the part, the part should become modifiable by Simulate.

- Open the part that has the surface (volume) you need to separate. Access Simulate from the Part, and cut the surface (or volume) from there. The cut will be inherited by Simulate opened from the assembly.