Community Tip - Did you know you can set a signature that will be added to all your posts? Set it here! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Cylinder Assembly Issues

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Cylinder Assembly Issues

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Cylinder Assembly Issues

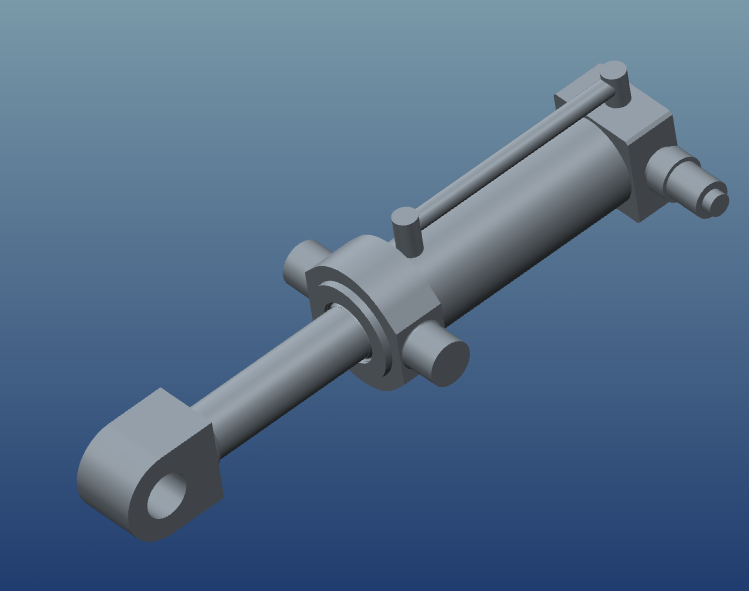

See below simplified model.

This is a model of a hydraulic cylinder I use in the manufacture of a number of chambers for the rock crushing industry.

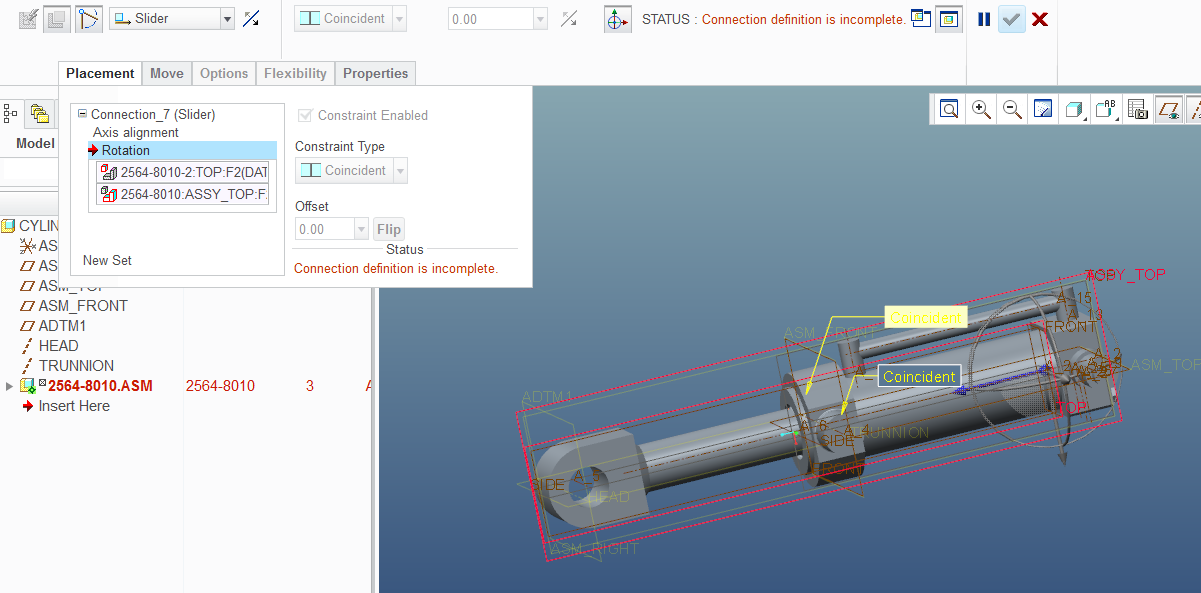

The rod is assembled into the cylinder with a slider constraint, limited to the stroke of the cylinder as below

It is typically assembled into the subassembly on a pin constraint (the trunion axis and the central planes) and the head of the cylinder is on a cylinder constraint (2 axes)

this works perfectly in a simplified assembly. but when this is installed into a larger assembly on a skeleton it is unable to maintain the connections.

any guidance would be welcome.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

Assembly Design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

First thought would be to try making all connections as cylinder connections. This should give the assembly some ability to adjust if needed.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Kevin,

Thanks for your response, I have tried this without success unfortunately. I have also tried non-mechanism based constraints ( simple coincident etc), but this failed also.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Is the slider constraint defined for the subassembly or is it a part constraint between the cylinder and cylinder housing that make up the subassembly? Also are you using references from the same parts or assemblies for the different constraint elements, the rotation element has an assembly reference what does the axis element have for a reference? For situations such as you are describing it's been my experience that pin connections are too restrictive because it only allows in plane motion. Also based on the experience I've had with slider constraints just like the pin it could be too restrictive for the motions your assembly would encounter. It also might help if you could show what the references are for the other connection elements to see if there is something that would show as causing a conflict.