Community Tip - Learn all about the Community Ranking System, a fun gamification element of the PTC Community. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Assembly cut?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Assembly cut?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Assembly cut?

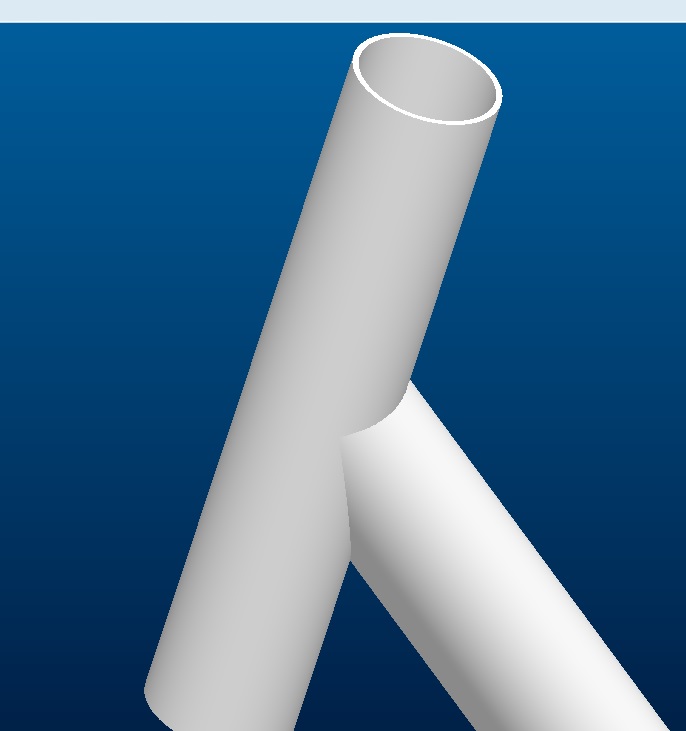

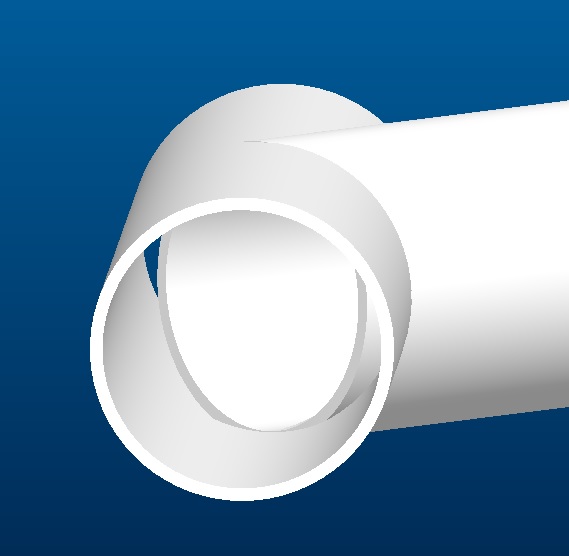

Is this a cadidate for an assembly cut?

Actually my parts are both curved, but I thought I state simple with two pieces of tubing, one at a 45 degree angle to the other. The one at the 45 will be cut before being welded to the other (no holes in the parent parent part - just structural). How would you go about making the cut to the 45 degree piece?

The material that needs to be removed in order to nest them together before weld.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

Assembly Design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is a candidate for the top down design process. You would make the edits in the assembly with the 45 degree tube active. You can use the vertical tube for its diameter reference, location, and even the projection plane.

Just remember that you now have a dependent reference. You can unlink it manually when you are back in the 45 degree part but sustainability is a nightmare. You have to decide if top-down design models are acceptable in your organization.

You can also consider a skeleton model that holds all the tube centerlines. In this way, you can reference only one model for all your assembly references in lower level parts. This is normally much preferred since you will minimize the number of dependent files to 1 (+assembly).

I am working on a bike frame myself (a reverse engineering session for posterity) and I am not using separate tubes. I am modeling the weldment at a part level. If I need tube prep drawings, I would use assembly cut to cut up the master part into the individual pieces. This may seem backwards, but in this way, the "master" is a part file with the prep'd tubes as subordinates rather than masters. In this way, I am reducing the corruption penalty and the final level assembly part count is actually much smaller. The individual tubes are now independent from the overall assembly but dependent on the inseparable weldments which becomes the parent. If all that makes sense.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Now if the tube on the left (parent tube) had a bend radius, how would you use it to remove the material from the 45 degree tube (child)?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

A datum point at the radius center; optionally an axis.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I go with Tom but then TDD is pretty much second nature to me.

If you don't have this or simply want to do it another way then:

Make an assembly surface of the outside of the parent tube then use this to cut your child part. Never tried to make the cut in assembly but you could definitely make the surface of the parent in the child while in assembly and do the cut in the child. Definitely creates cross references and these can get very tangled up if you are not careful (hence my preference for the formality of TDD). Also there can be an issue of cross referencing not being allowed in your setup (by system admin). You are allowed cross references by default in ProE/Creo but configs can be set to limit or disallow such references.

Do the same thing but activate the child and Copy the outer surfaces from the parent then use this quilt to cut away the unwanted "intersection". This is probably what I would do if I did not have TDD.

You can hunt and peck at cutting away the "intersection" as made up features in the child but there is no guarantee that if you update the model to say 50° then the "intersection" will no longer be valid and must also be manually updated. Do not recommend this as it is a minefield for later.

Regards, Brent

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Tubular construction with top-down design:

Check this video:

http://www.e-cognition.net/pages/Tubular.html

Usually l have problem with windows media player on this website. Download new version or download video directly due the text row above the video window.

Hope it will be helpful...